Spring energized lip seals

High demands on sealing elements require extraordinary solutions. Spring energized lip seals are such an extraordinary solution. The well thought-out selection of the material and a seal design adapted to the respective conditions results in a variable sealing system that can withstand extreme operating conditions and parameters.

The benefits in brief:

- Temperature range from approx. -250°C to +300°C

- Chemical resistance against almost all medias

- Low friction coefficient

- No stick-slip-effect

- Diameter range from 2 mm to 3000 mm

- No tool cost

In addition to a wide range of standard products, we provide you with the right seal design for your application. There are almost no limits to the design and size.

General technical information, applications and industries

Spring Energized Lip Seals (PTFE Seals)

Components:

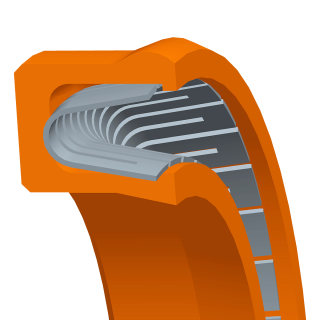

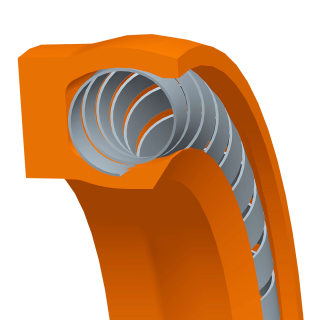

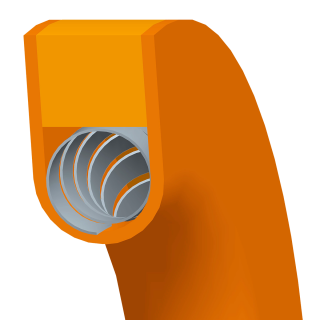

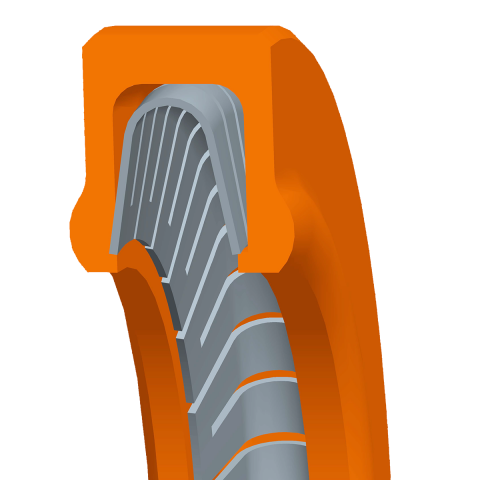

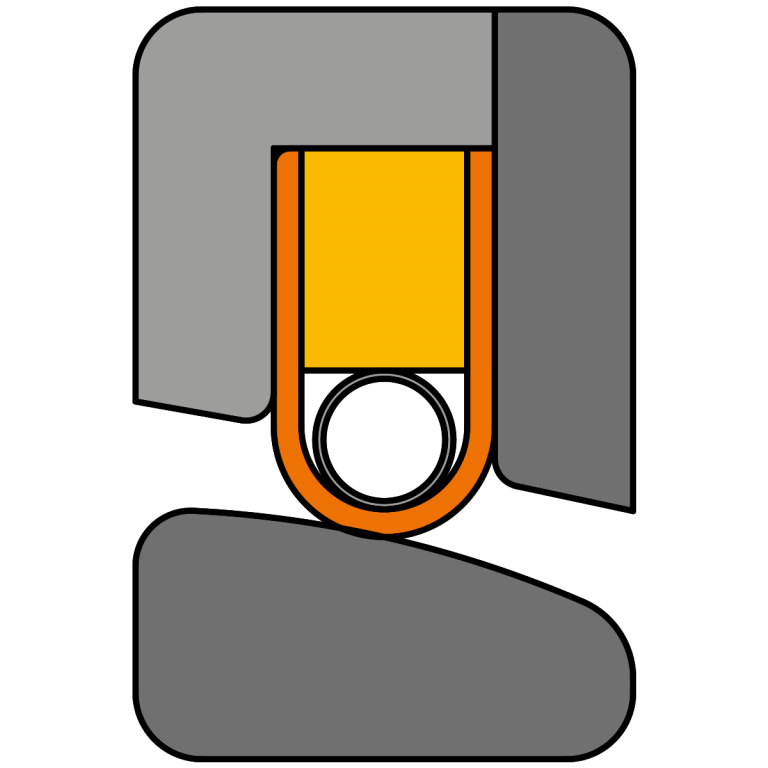

Normally, spring energized seals consist of a jacket made of highly stressable plastic/plastic compounds and an embedded preloading element made of different materials.

Among other plastics, polytetrafluoroethylene, or PTFE for short, is the most suitable material for the seal jacket. Also known as Teflon, this polymer has special properties due to its chemical structure. The arrangement of the fluorine atoms around the carbon atoms creates a kind of protective layer, which generates almost universal chemical resistance. Only a few media, such as elementary fluorine or alkali metals, can affect the plastic. Furthermore, PTFE has a low friction coefficient, which makes it predestined for use in dynamic applications. In addition to high temperatures up to 300°C, PTFE is also used in cryogenic applications. By admixing additives, the properties of PTFE can be modified and adapted to the respective application. PTFE is a sintered material which is brought into the desired shape by machining. This allows a wide range of variants to be produced without tooling costs.

Different variants and materials are available as preloading elements or springs, which are also adapted to the respective application. In addition to corrosion-resistant stainless steel, alloys for higher requirements are available. The use of elastomeric materials is also possible. The preload elements essentially determine the force characteristics of the seal and will be adapted to the respective application. Due to the in-house production of the spring elements we have a wide range of different materials and special dimensions.

Typical applications / Industries

- Machine- & Plant Construction

- Tool turret - Oil & Gas

- Butterfly valve

- Ball valve

- Cryo temperature - Sealing Technology

-Mechanical seals - Chemical & Process Technology

- Filling systems

- Dispensing technology - Medical & Food Technology / Pharma

- Endoscopy

- pipetting heads

- HPLC pumps - Laser & Sensor Technology

- Optical measuring machines

- CO2 laser cutting heads

- ultrashort pulse laser - Aviation & aerospace

- Satellite telescopes

- Fuel tanks

- Fuel systems

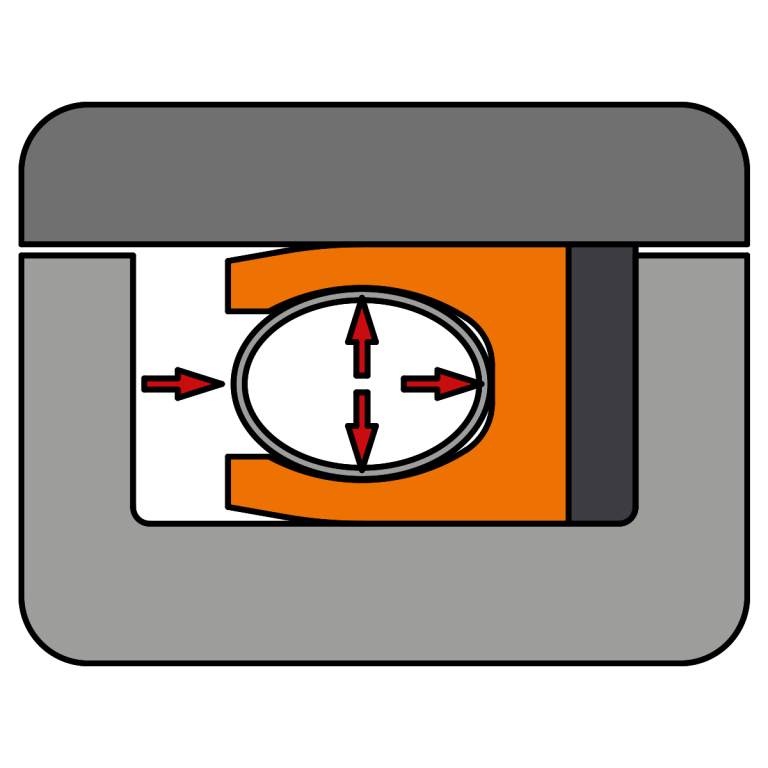

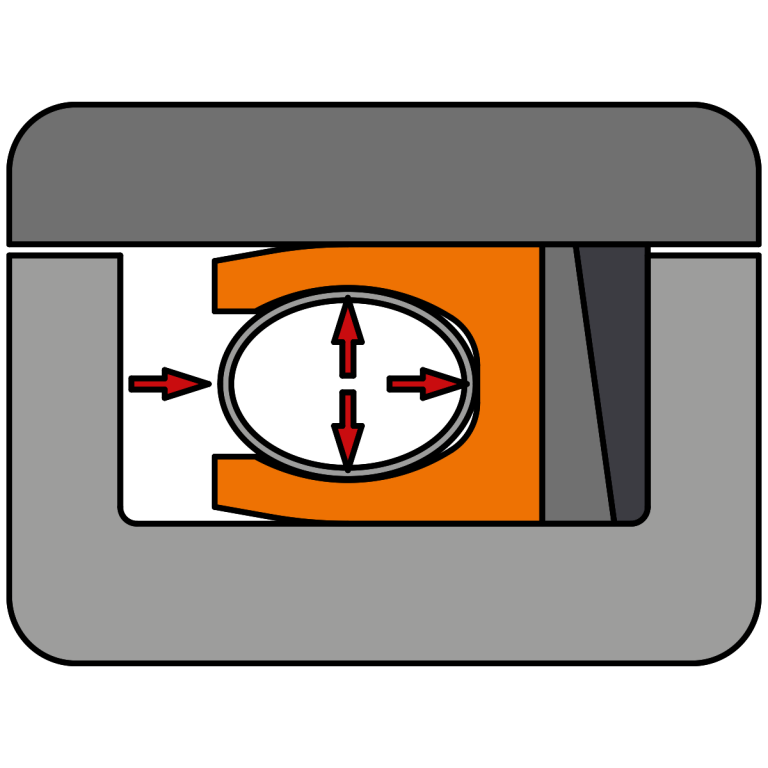

Mode of action

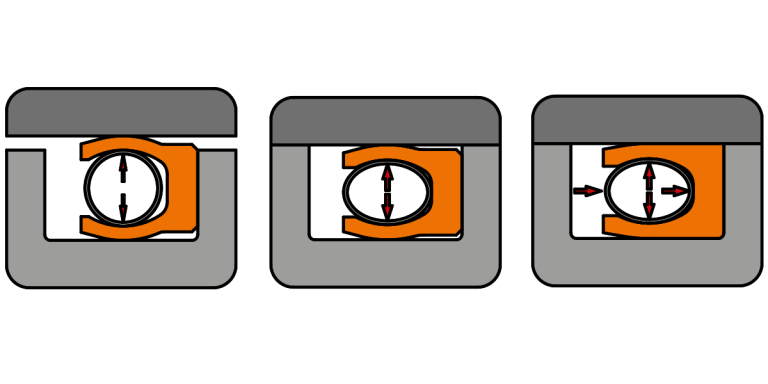

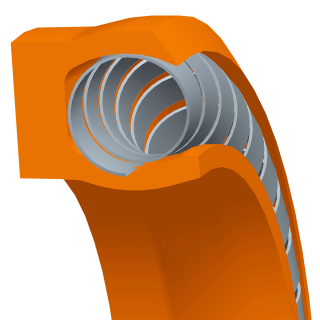

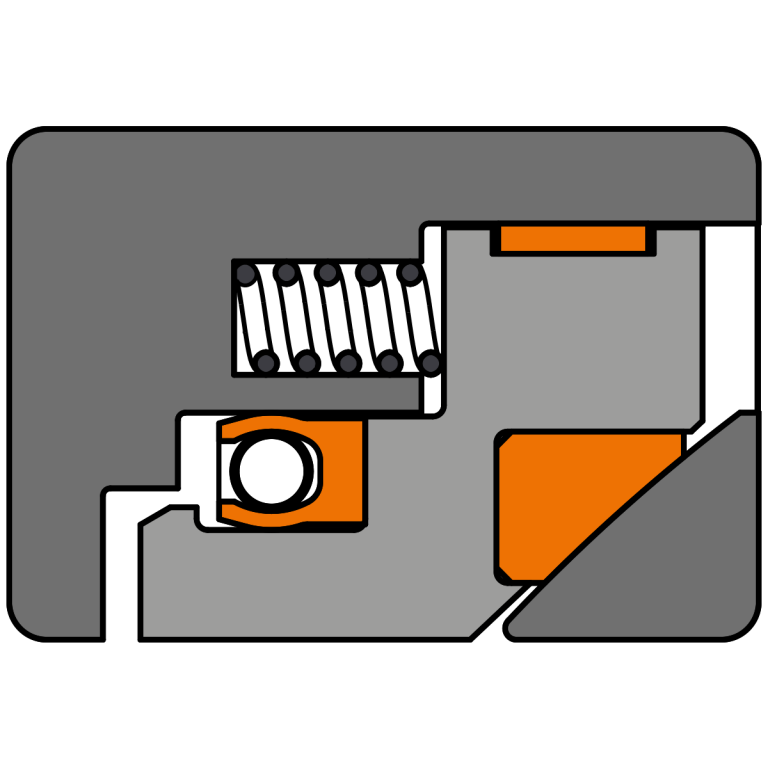

The behaviour of a spring energized seal follows the functional principle of an elastomer O-ring.

During installation, the seal is compressed and creates a pressure on the sealing surfaces primarily by the spring. As a rule, the higher the force of the spring, the higher the tightness. The actual system pressure increases the contact pressure and thus the sealing effect.

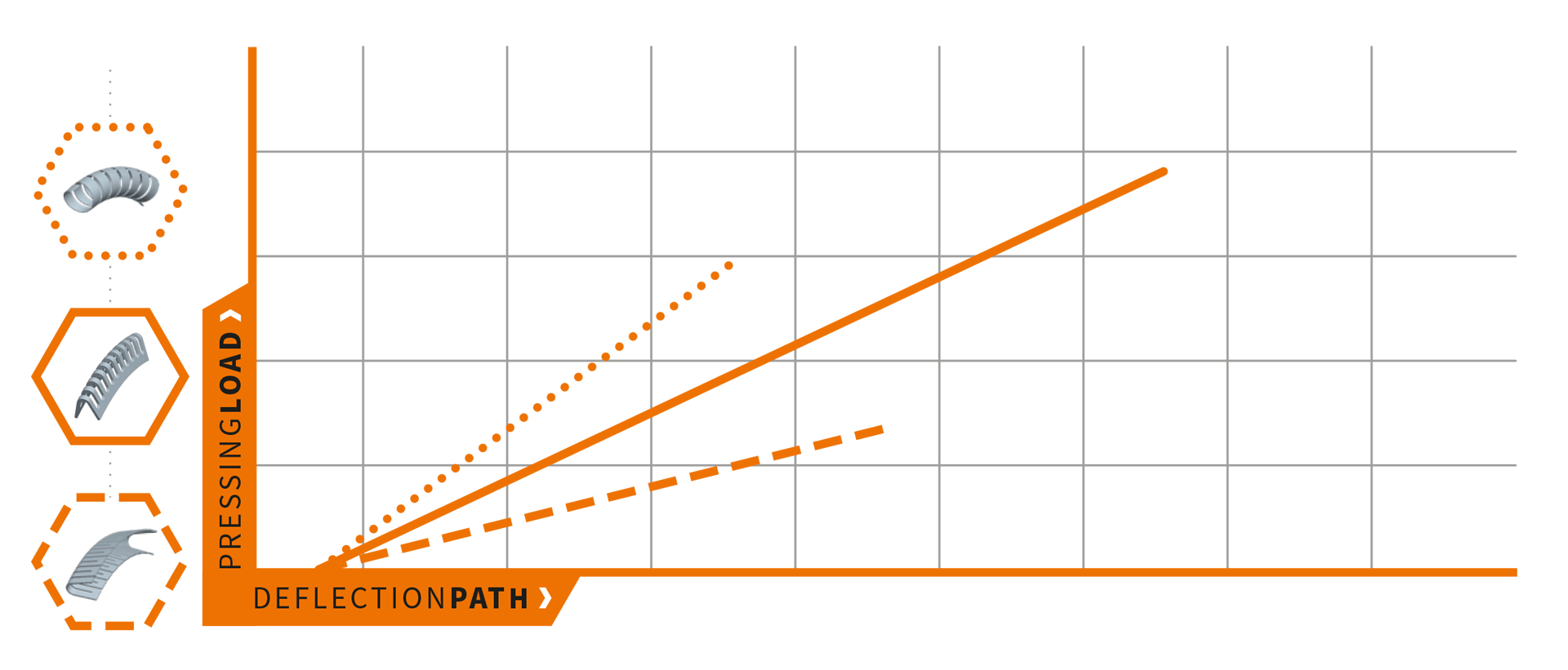

Depending on the required force application, different spring variants can be selected. These differ in the ratio between the pressing stroke and the pressing load as shown in the following diagram.

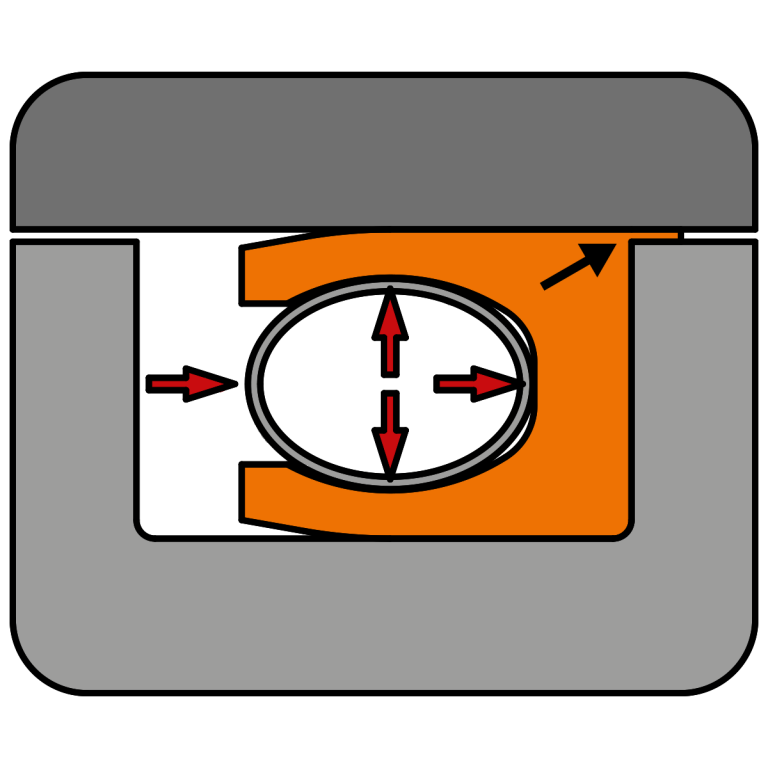

Cold flow behavior

The gap behind the seal is decisive for the effect and the service life. This gap occurs primarily in radial seals or is necessary for design reasons. Since plastics tend to flow, this gap must be kept as small as possible to avoid extrusion into the gap. This phenomenon is significantly intensified with increasing pressure or temperature.

To counteract the cold flow, different arrangements of support rings made of pressure-resistant material are used.

Our technical department will be pleased to advise you on this.

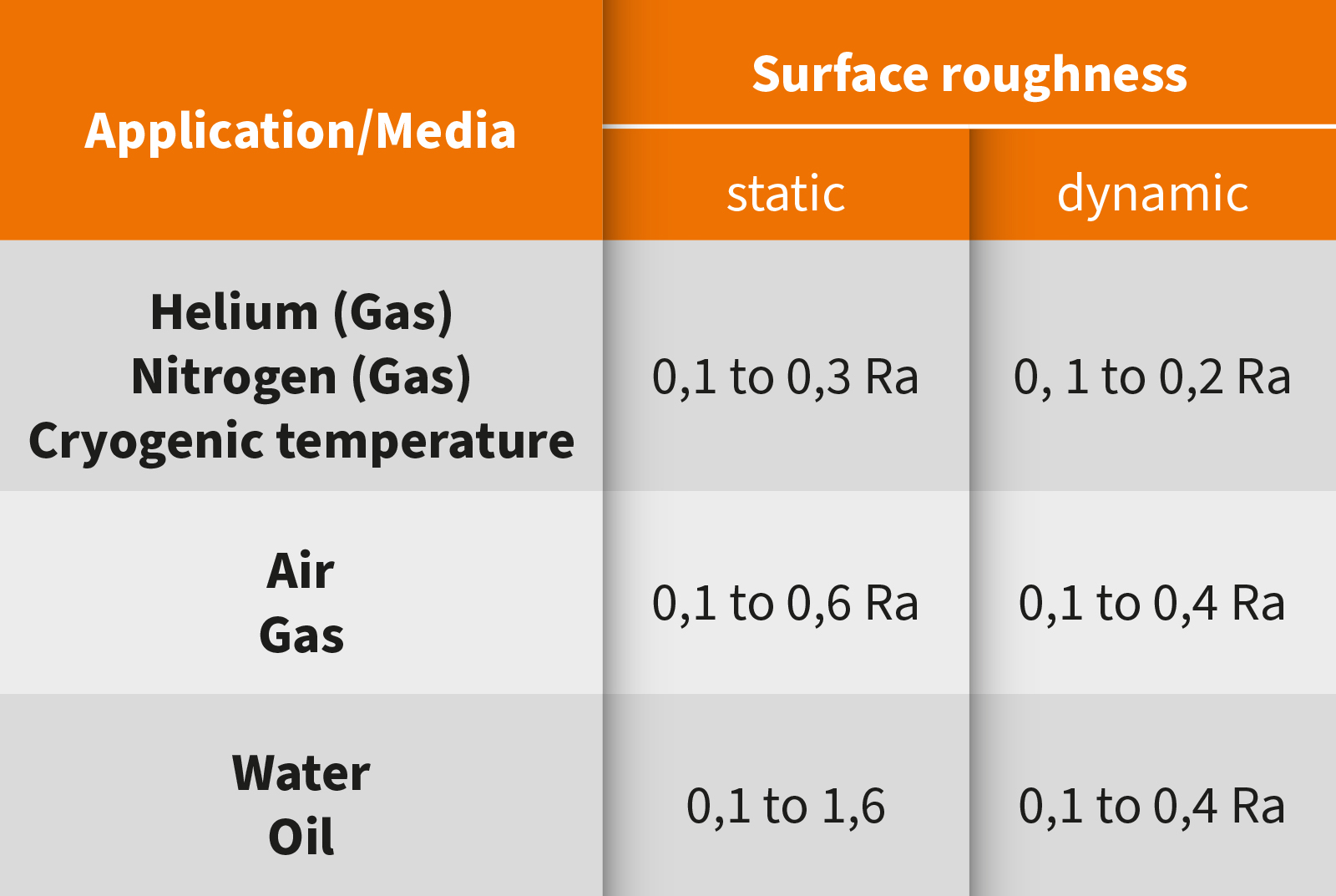

Surface finish

Spring energized lip seals require a comparatively high standard of surface quality for the sealing surfaces. In general, the better the surface, the better the sealing effect and also the service life of the seal due to less wear. The best possible surface quality should be aimed for, especially when sealing gases and in the cryogenic area.

In addition, the surface hardness of the sealing surfaces also determines the wear resistance of a dynamic seal. Soft sealing surfaces can be damaged by abrasive particles, which must also be considered when selecting the correct seal material. A hardness of approx. 55-60 HRC should be maintained as a guide value.

Assembly and installation

Technical recommendations

Care should be taken when installing a spring energized lip seal. Installation over sharp edges should be avoided and there should be sufficient lead-in chamfers.

Since the seals are only slightly expandable, split grooves should be used. However, installation in closed grooves is possible in individual cases. Please contact our technical department.

Materials

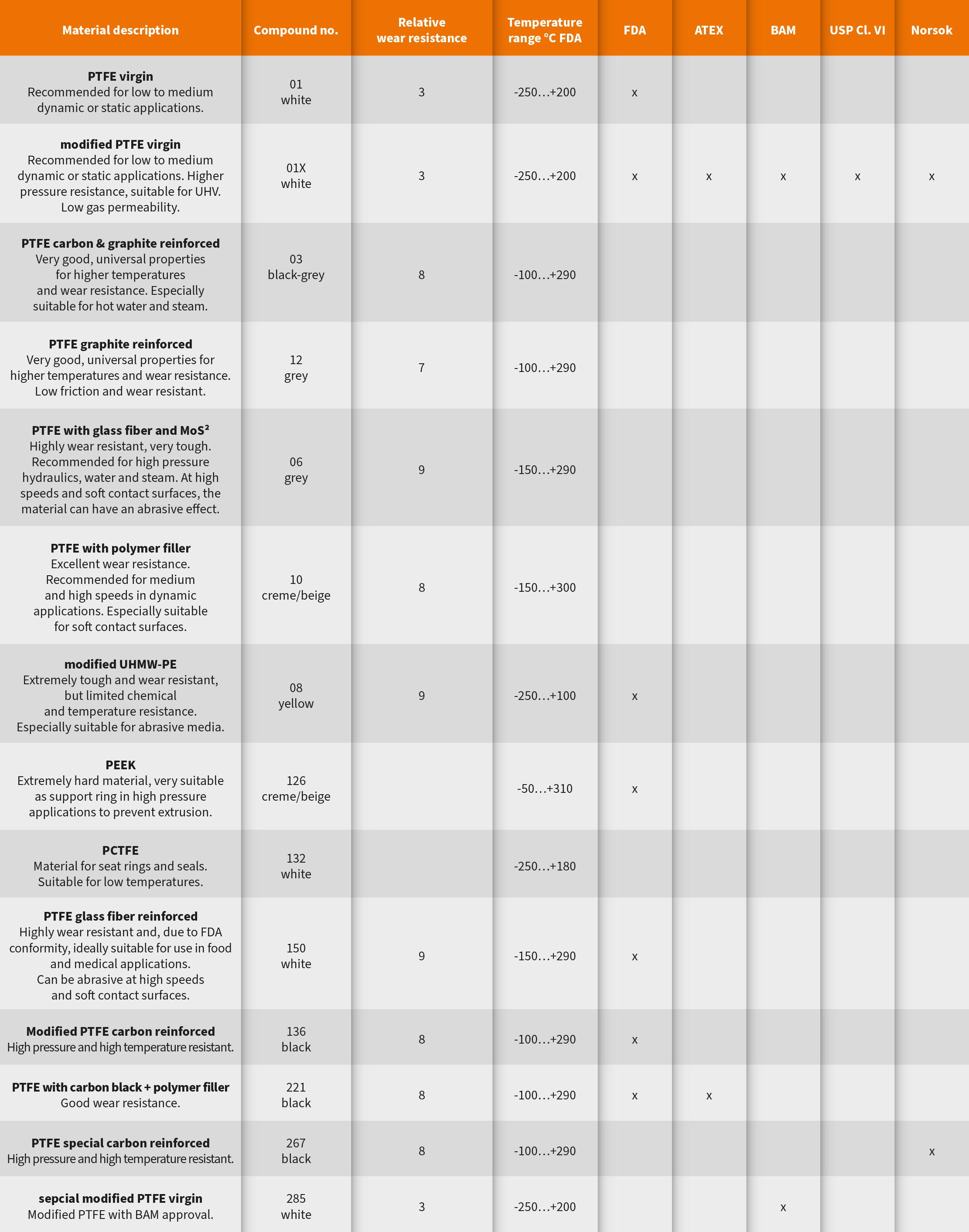

Jacket material

More than 250 compounds are available for the material of the seal jacket for a wide range of applications. A selection of these can be found here in the table.

In addition, individual compounds suitable for your application are also possible.

Please contact our application technology department.

Preload elements

Radial Seals

Design overview

Apart from the standard shapes listed below, we develop variants customized to the respective application.

Our technical department will be pleased to advise you.

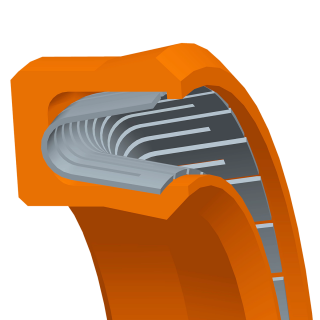

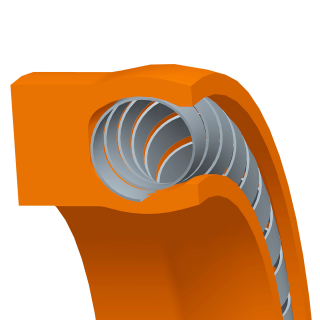

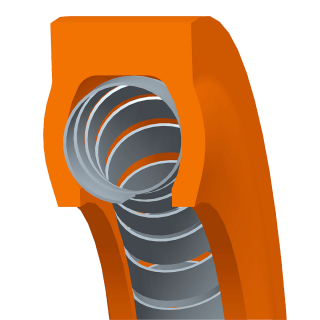

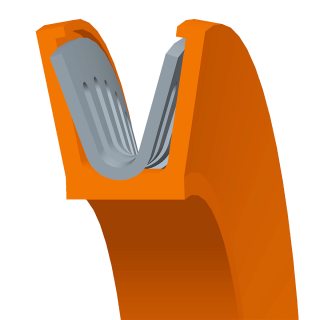

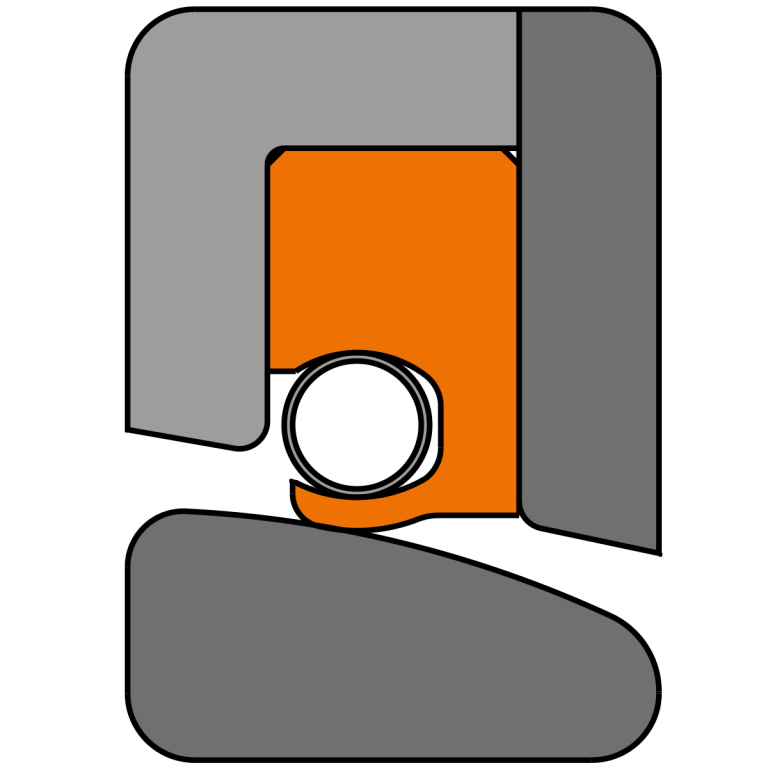

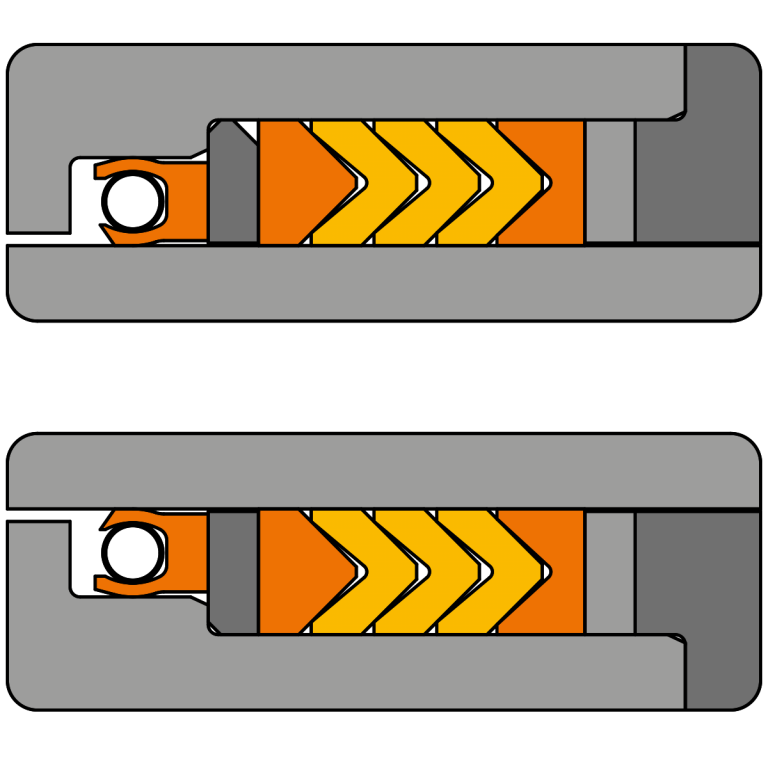

Type 400

Standard type with inserted V-spring, symmetrical with rounded sealing lips. Particularly suitable for dynamic applications due to the high flexibility of the sealing lips and low friction

Other types and variants of type 400

Type 401

Sharp scraper edge on the inner diameter, suitable as a rod seal for translational movement of fluids

Type 402

Sharp scraper edge on the outer diameter, suitable as piston seal for translational movement of fluids

Type 4VS

Symmetrical design with chamfered sealing lips on both sides, suitable shape for dosing fluids

Type 414

With retaining flange as anti-rotation device to prevent the seal from rotating, especially suitable for rotary applications

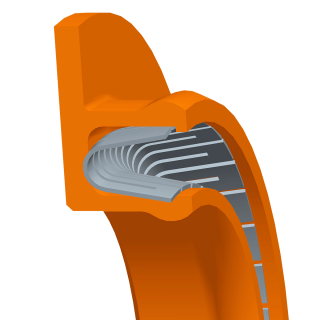

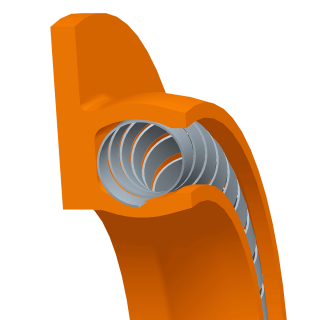

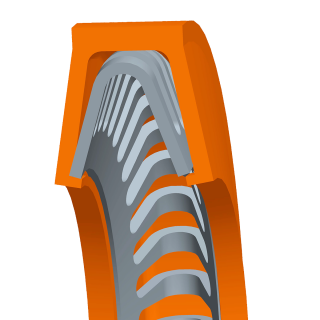

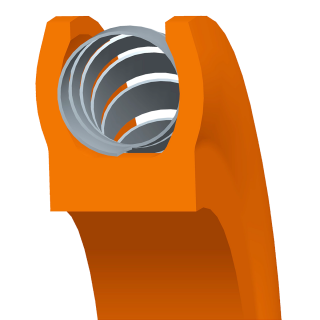

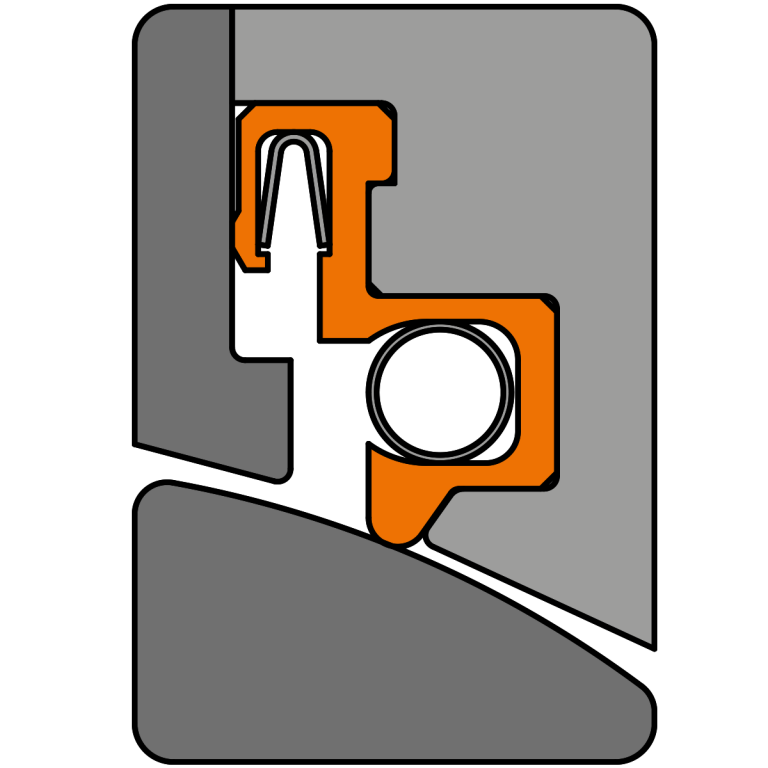

Type 103

Standard type with inserted coil spring, symmetrical with rounded sealing lips, particularly suitable for static or slightly dynamic applications due to the high spring forces

Other types and variants of type 103

Type 113

Sharp scraper edge on the inner diameter, suitable as a rod seal for translational movement of fluids

Type 123

Sharp scraper edge on the outer diameter, suitable as piston seal for translational movement of fluids

Type 143

With retaining flange as anti-rotation device to prevent the seal from rotating, especially suitable for rotary applications

Special designs for special requirements

Lip seal without housing

Radial lip seal made of wear-resistant plastic compound. The design is freely selectable and is determined on the basis of the application parameters.

More detailed information on the wide range of possibilities can be found in the lip seals section.

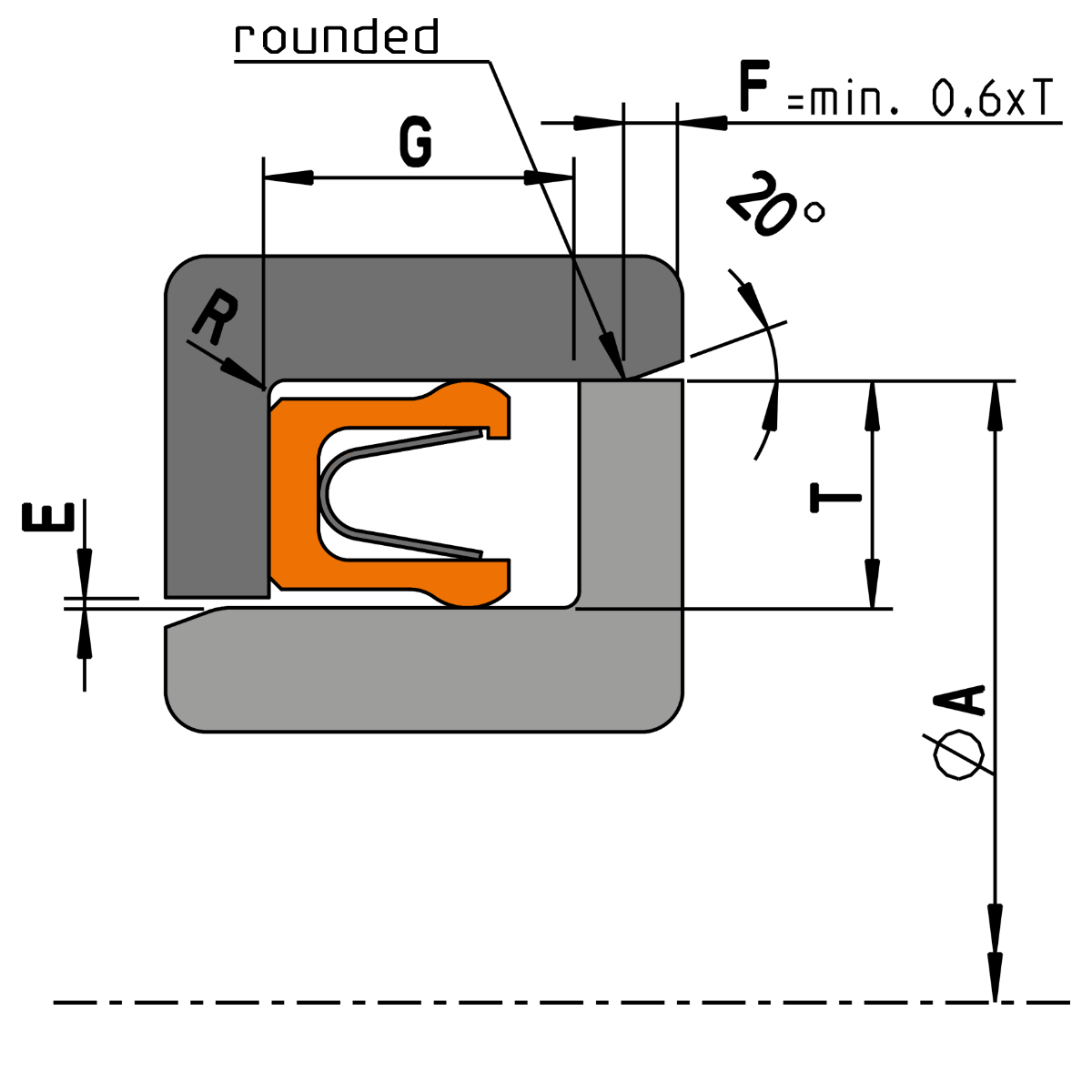

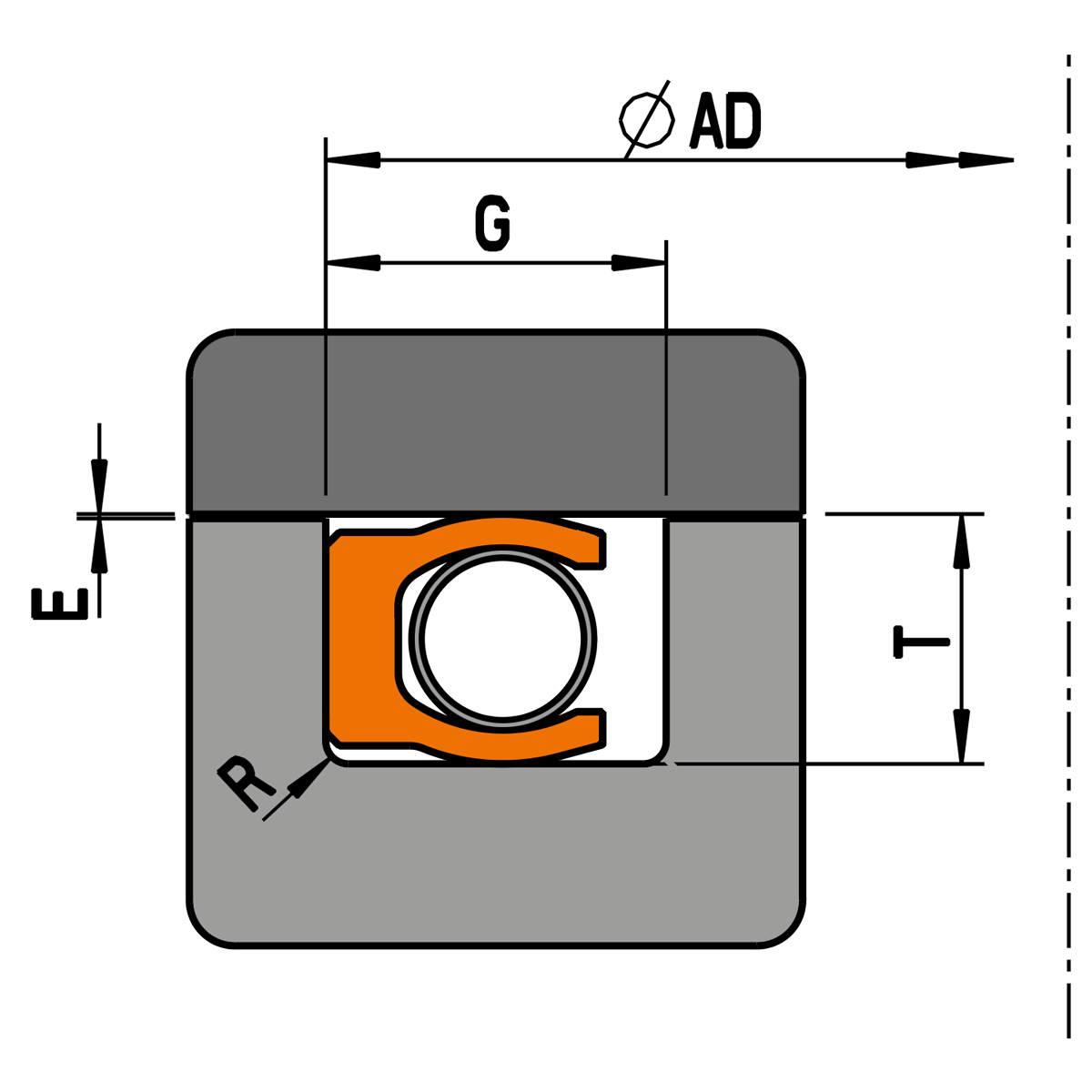

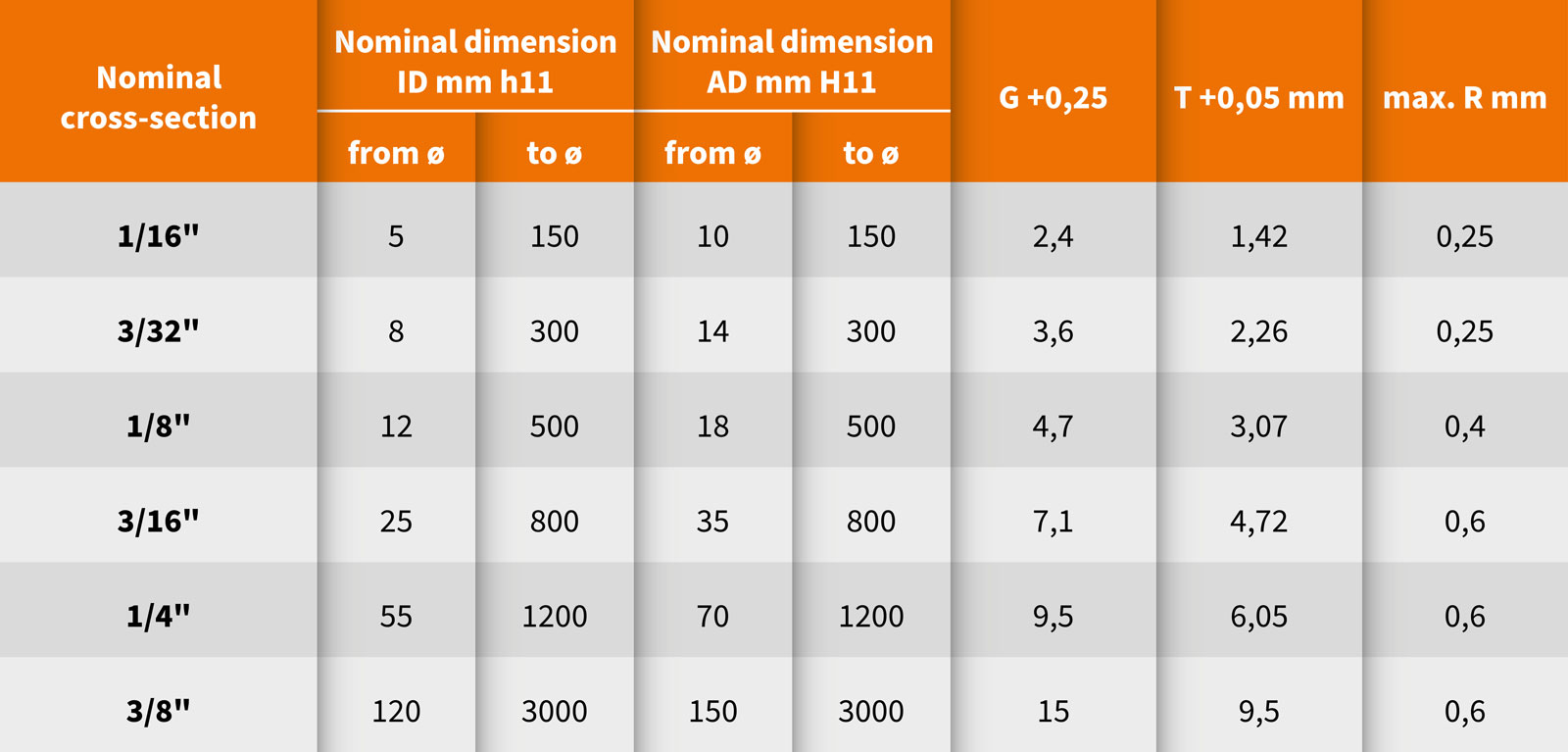

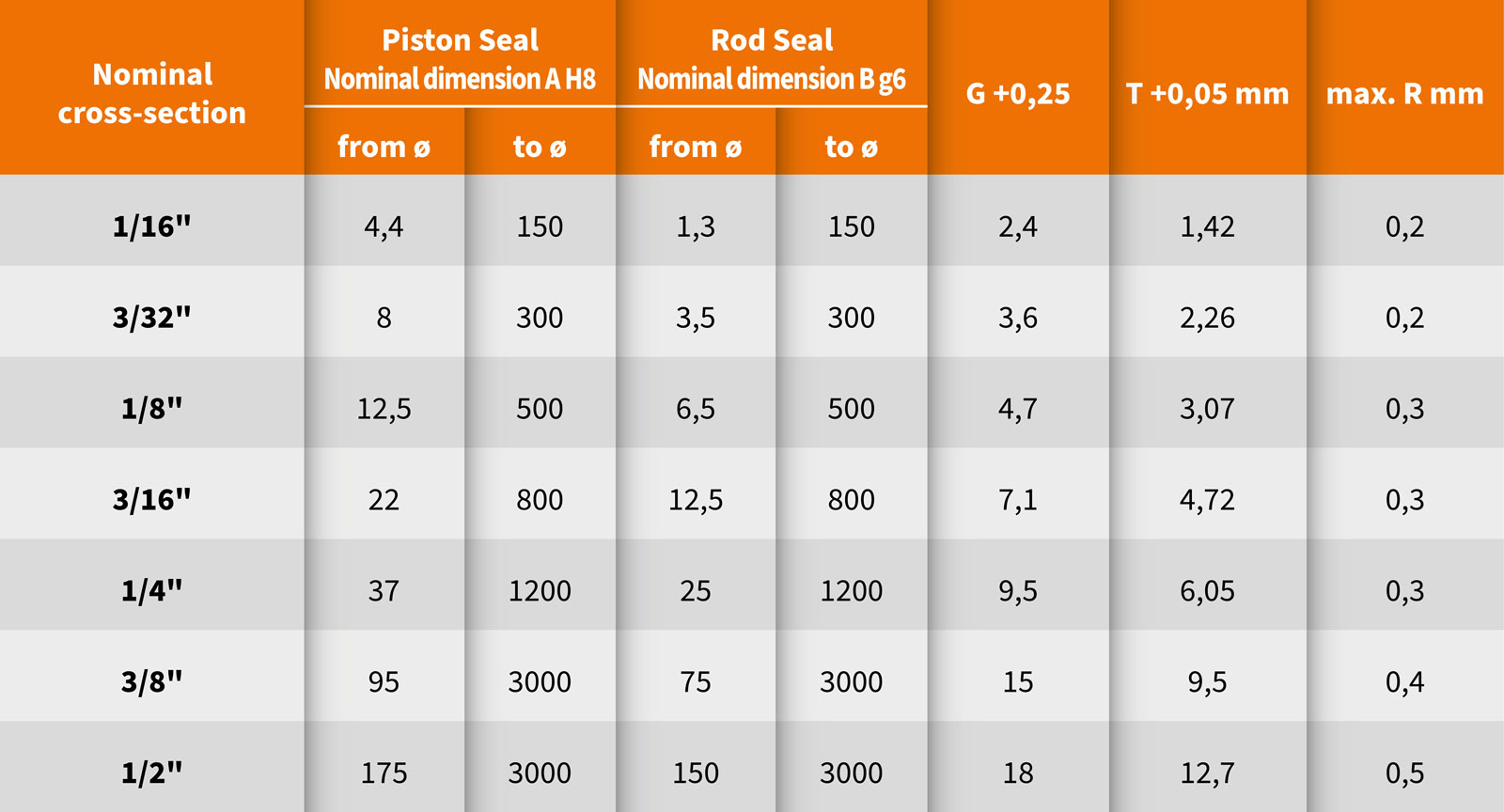

Installation and groove dimensions

The gap "E" behind the seal is decisive for the service life of the seal. In general, this gap must be as small as possible to prevent cold flow of the material. The maximum gap depends on the application parameters, such as pressure and temperature. Please contact our technical department for further information.

Standard sizes

In addition to the following standard sizes, we are able to adapt our seals to existing groove geometries or create a solution customized to the respective application. The specified diameters are only approximate values. If you have any questions, please contact our technical department.

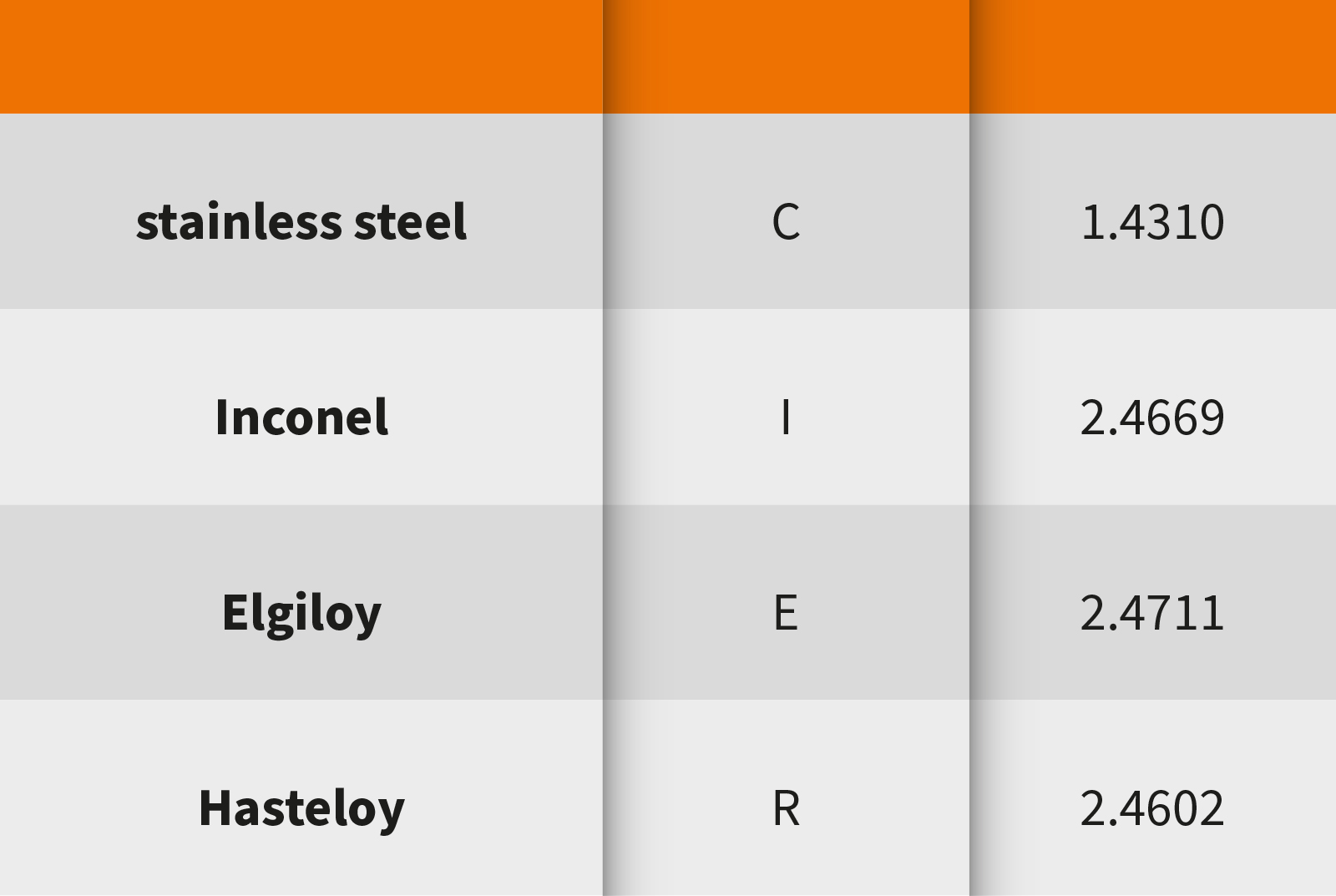

Preload element

Materials

The abbreviations C I E R denote the last digit of the matchcode. Other materials available on request.

Other materials available on request

Other materials available on requestSeal description

Matchcode

The following information is generally sufficient for the seal definition of standard seals:

For special dimensions it is also sufficient to specify the groove dimensions, e.g:

103-B 250 x 270 x 15-06-E

Axial seals

Design overview

In addition to the standard shapes listed below, we also develop customized versions for specific applications. Our technical department will be pleased to advise you.

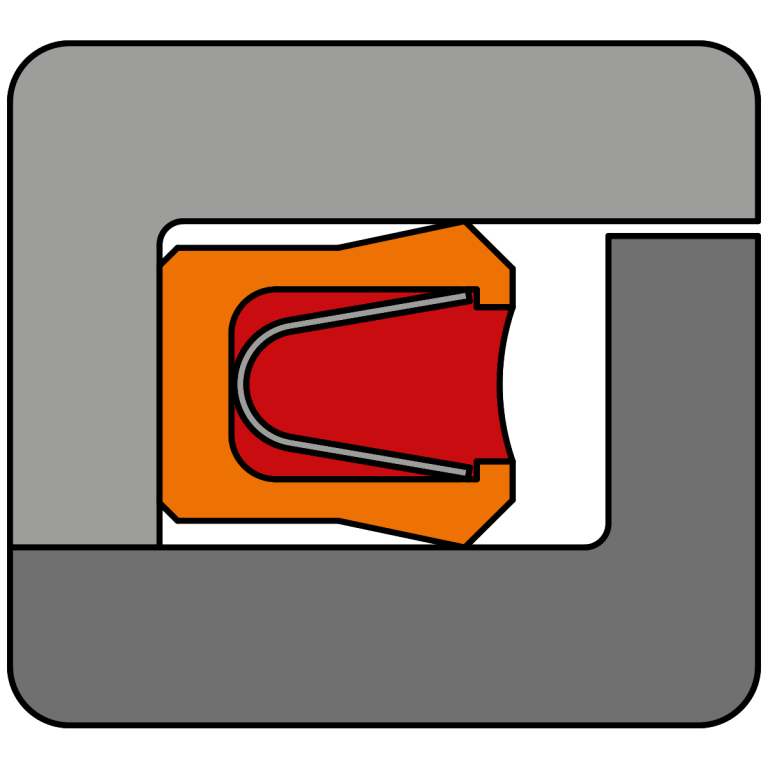

For internal pressure

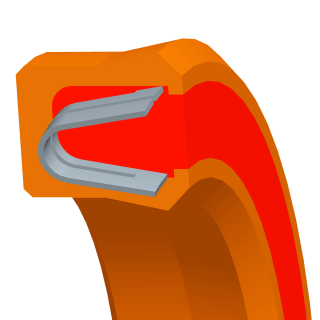

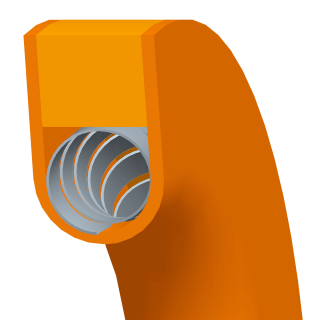

Type 403

Symmetrical design with rounded sealing lips for dynamic and static applications, inserted V-spring

Other types and variants for internal pressure

Type 304

Symmetrical design with rounded sealing lips for dynamic and static applications, high pressing force due to inserted coiled spring

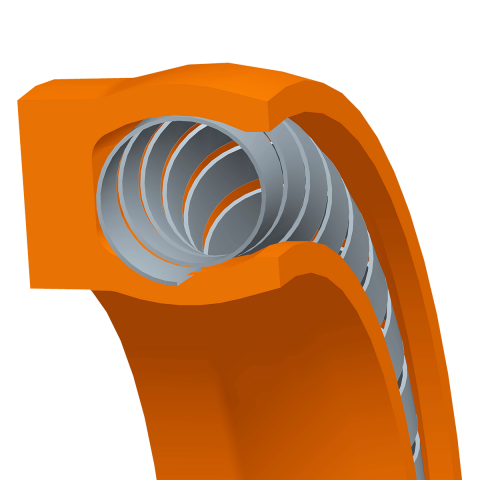

Type 1100

For static to slowly dynamic applications such as swivel joints, high pressing force and large pressing stroke, full contact spring

Type 2100

For static to slowly dynamic applications such as swivel joints, high pressing force and long pressing stroke, with inserted steel ring to increase stability

For external pressure/vacuum

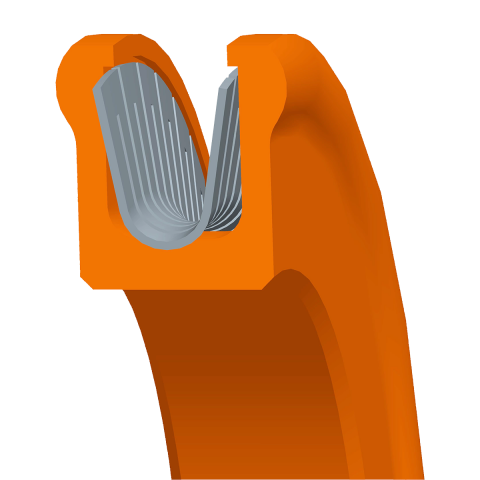

Type 404

Symmetrical design with rounded sealing lips for dynamic and static applications, inserted V-spring

Further types and variants for external pressure/vacuum

Type 314

Symmetrical design with rounded sealing lips for dynamic and static applications, high pressing force due to inserted coiled spring

We also supply special sizes, special profiles, different variants and special designs.

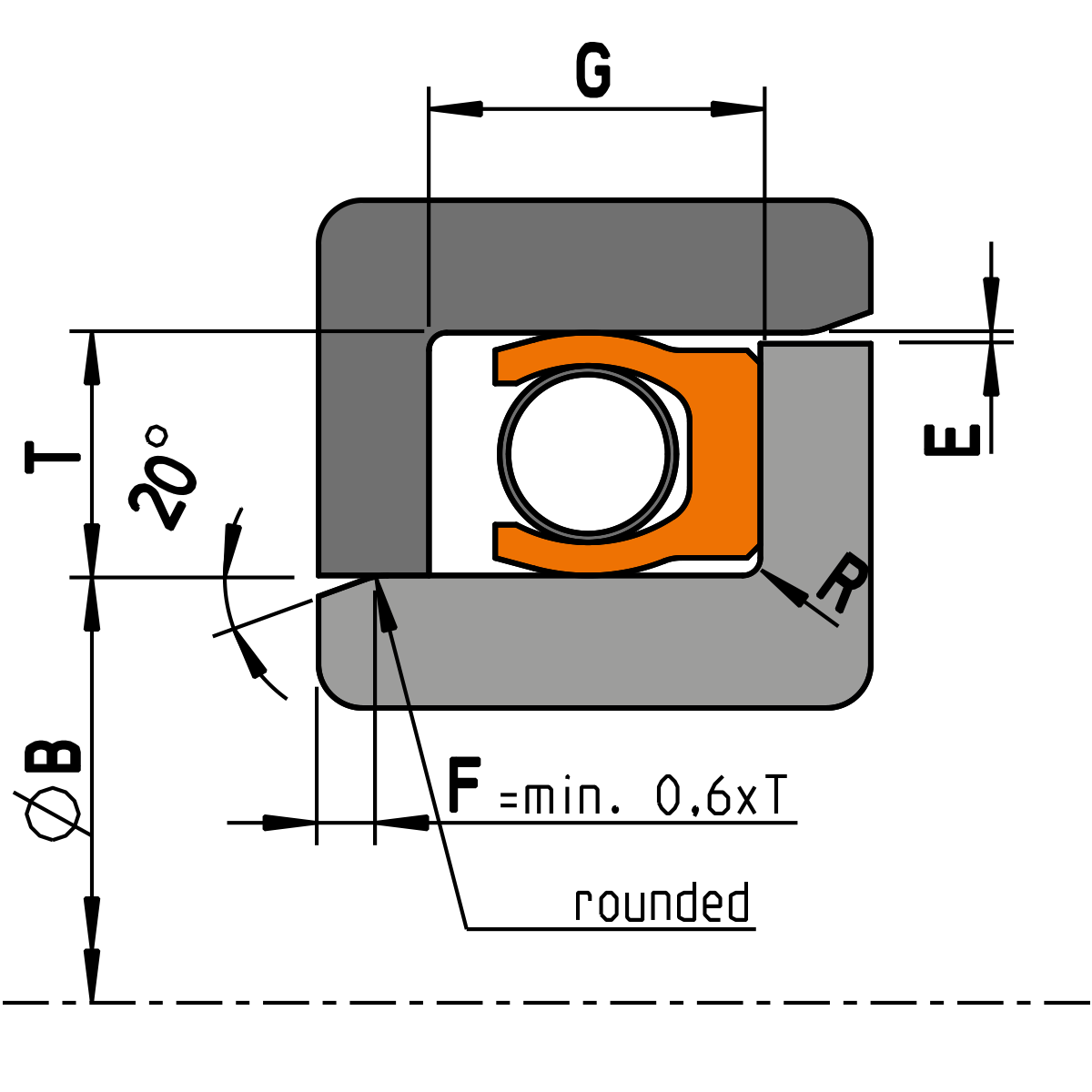

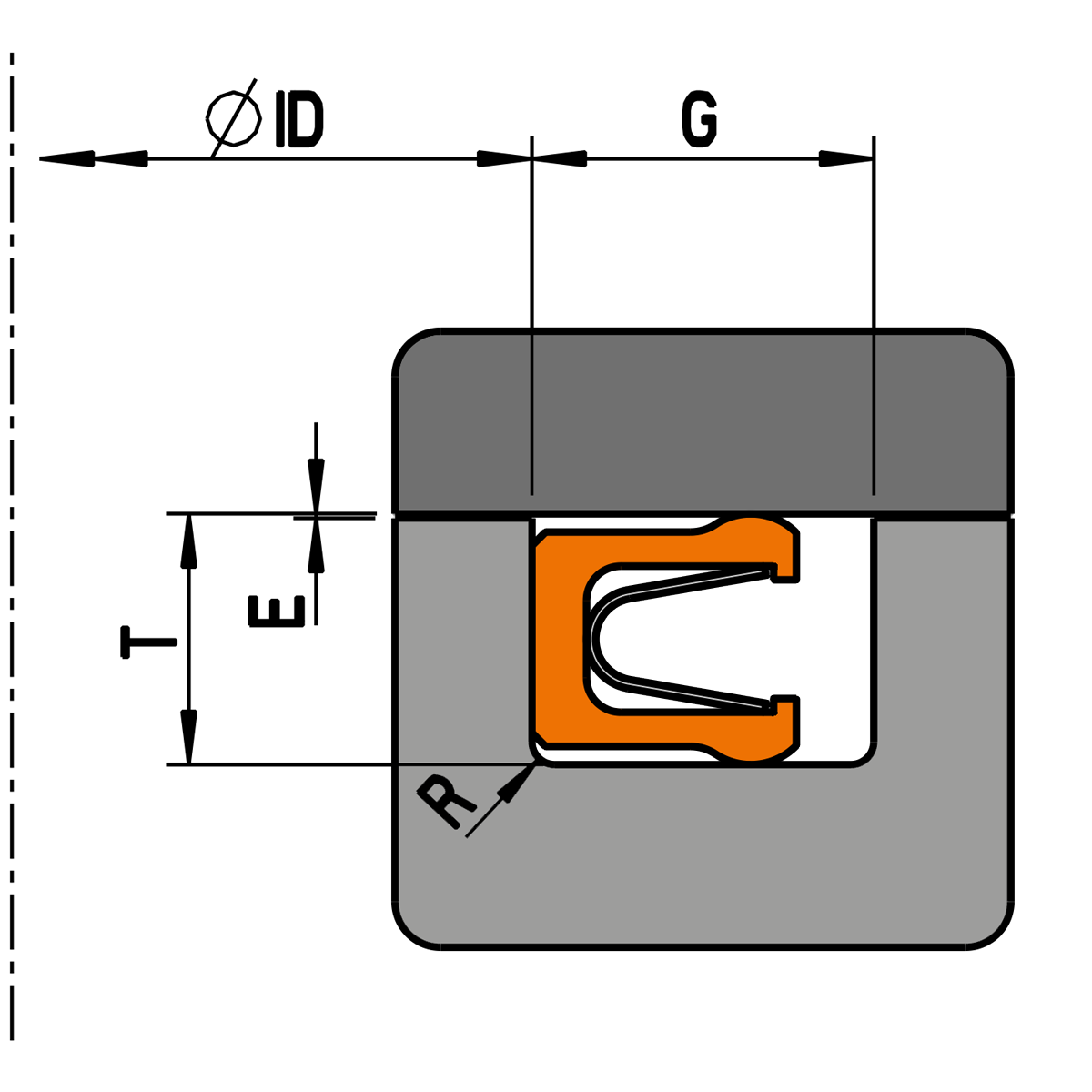

Installation and groove dimensions

For dynamic applications, such as a swivel joint or under certain operating conditions, a gap behind the seal may be necessary in the design or a gap may form. In general, this gap must be as small as possible to avoid cold flow of the material. The maximum gap "E" depends on the application parameters, such as pressure and temperature. Please contact our technical department for further information.

Standard sizes

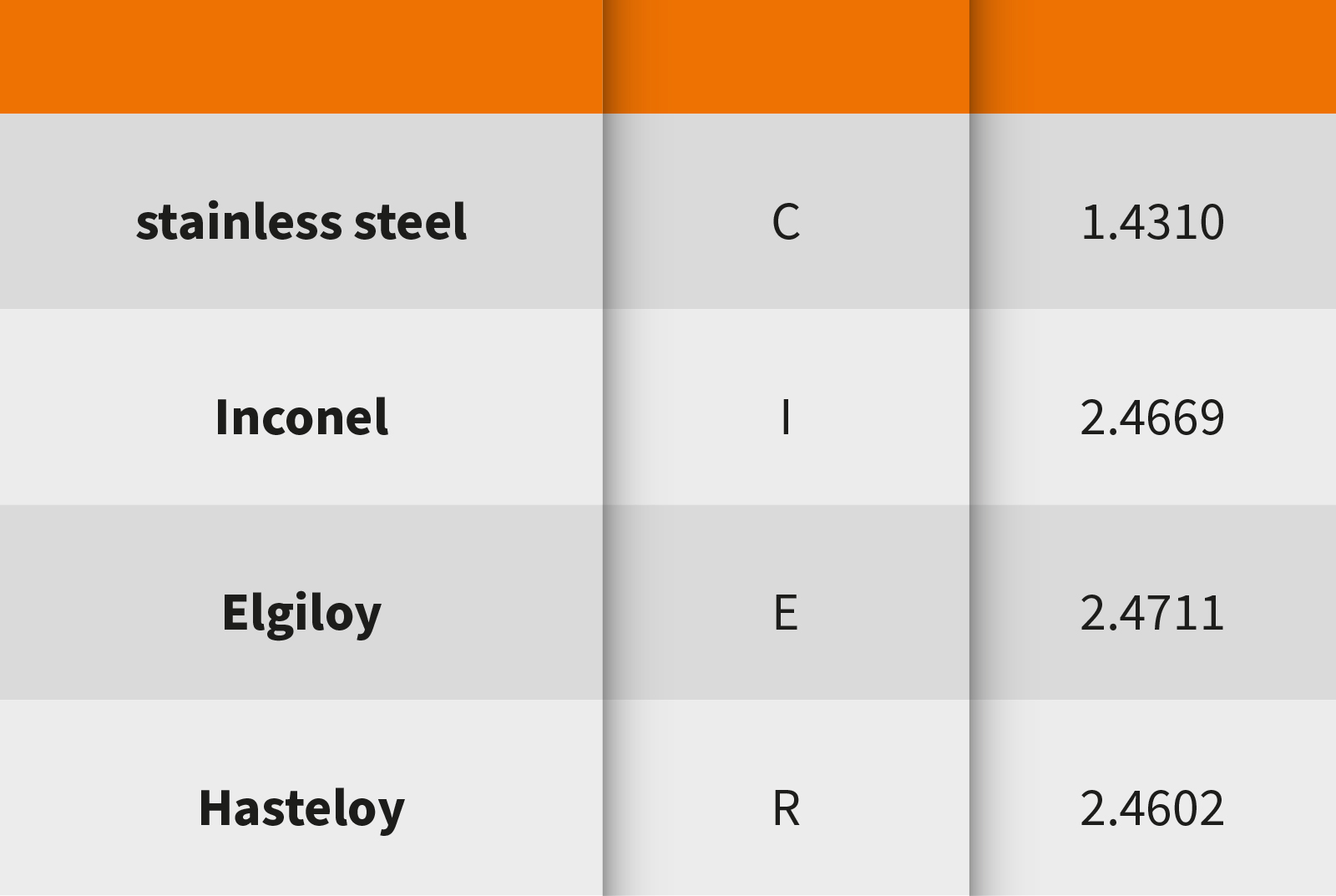

Preload element

Materials

The abbreviations C I E R denote the last digit of the matchcode.

Other materials available on request

Other materials available on requestSeal description

Matchcode

The following information is generally sufficient for the seal definition of standard seals:

For special dimensions it is also sufficient to specify the groove dimensions, e.g:

404-B 250 x 270 x 15-06-E

Individual solutions

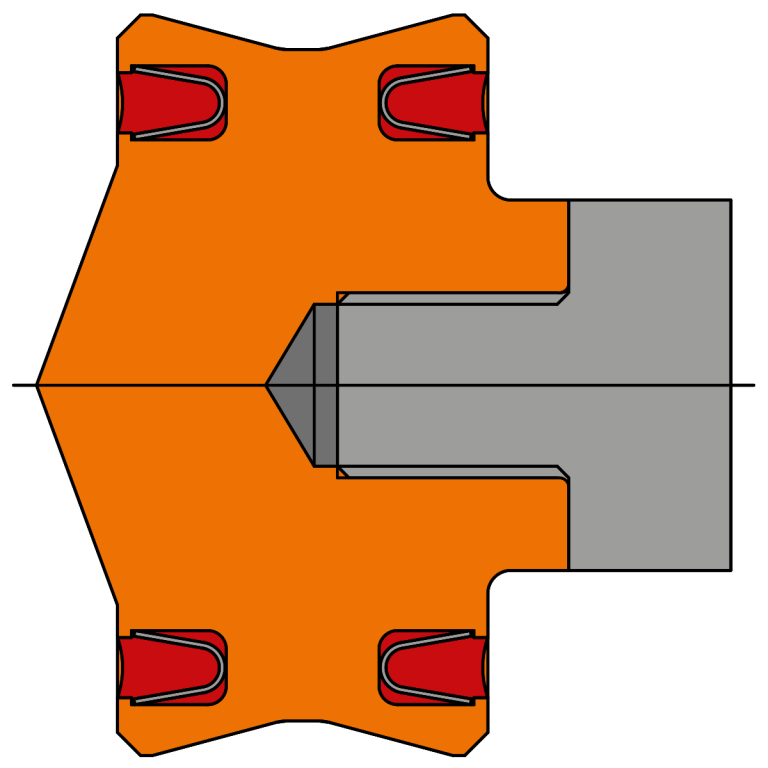

Solutions for valves

Valves that have to function at low temperatures of e.g. -196°C or in the desert, that have to be resistant to aggressive media, hot gases and pressures of several hundred bar, and at best with a long service life, require special solutions. We at GFD check your application individually and offer you a variety of solutions.

We supply solutions for a wide variety of valves such as ball valves, butterfly valves or control valves. We offer materials, which are tested and certified according to NACE/NORSOK/BAM.

If you have any questions, please feel free to contact our technical department. We have the right solution for your application.

Solutions for the food and pharmaceutical industry

This area ideally combines the material properties of chemical-resistant plastics and acid-resistant spring steel. The preloading element guarantees a high and permanent elasticity, which is not affected by cleaning or sterilization processes. We offer FDA and USP VI certified materials. If you have any questions, please feel free to contact our technical department. We have the right solution for your application.