Research and development

GFD - Gesellschaft für Dichtungstechnik mbH - innovative, constructive and uncomplicated.

For us these are not only adjectives. Short decision-making processes and flat hierarchies enable us to react flexibly and promptly to requirements and changes in the market.

To ensure the quality of our products, we are well equipped in the area of research & development. In terms of basic research, we have established ourselves with specially developed test facilities and test benches that are tailored to our products. We also have modern testing and measuring equipment at our disposal, which provides us with important findings even for project-independent basic research on materials and seal design.

Wherever possible we try to fulfill tests with our own equipment. But we also make use of the know-how and testing equipment of our external partners. This enables us to cover a wide range of required technical information on materials, material behaviour and other tests.

We are constantly expanding our testing facilities, depending on customer requirements and our internal demands in terms of basic research on new and alternative materials.

Currently we are able to perform the following tests with our in-house test benches and test equipment:

- Pressure and crack testing on spring energized lip seals

- Determination of the friction torque

- Determination of force characteristics

- Leak test on spring energized lip seals

- Helium leakage test bench

The knowledge gained supports us in the technical engineering of our products. With our extended know-how, we also create a technical basis based on facts for consultation and recommendations for incoming inquiries.

We would like to show you an extract of our possibilities here, we are able to check further requirements on request.

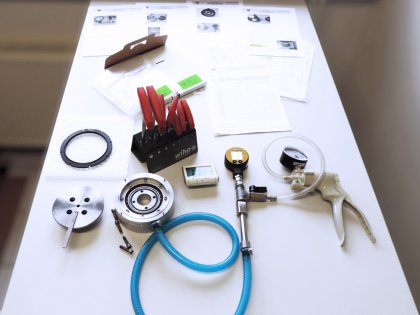

Determination of force characteristics and pressure test

on lip seals, axial

[Requirement: Testing of specified force value with subsequent pressure test]

In close cooperation with the customer, a test device was developed here in which the seal is pressurized. At a defined holding time, the pressure drop is documented and evaluated according to specifications. These seals are subjected to 100% of the above mentioned pressure test at GFD before delivery. The test device is also used for basic research on new materials and for simulating limit ranges.

Complete traceability enables us to react quickly to questions, even at a later date.

Pressure and crack testing

on spring energized lip seals, radial and axial

[Simulation of the application under high pressure]

The test conditions are composed as follows

Test medium: water

Pressure: up to 600 bar possible

Temperature: Room temperature

Holding time: variable or on demand

Test seals are manufactured in advance for the material batch release.

The test seals can then be subjected to a crack test under high pressure on a random sample basis.

If the test is passed successfully, the material batch is released for further use.

Various groove dimensions are available for the pressure test. The GFD pressure test stand was developed and manufactured according to the GFD requirements. The crack test provides important information regarding material behaviour under high pressure.

The tests are performed and documented in-house. The results of the tests flow into the application technology and serve the basic research by means of test series for new and existing materials.

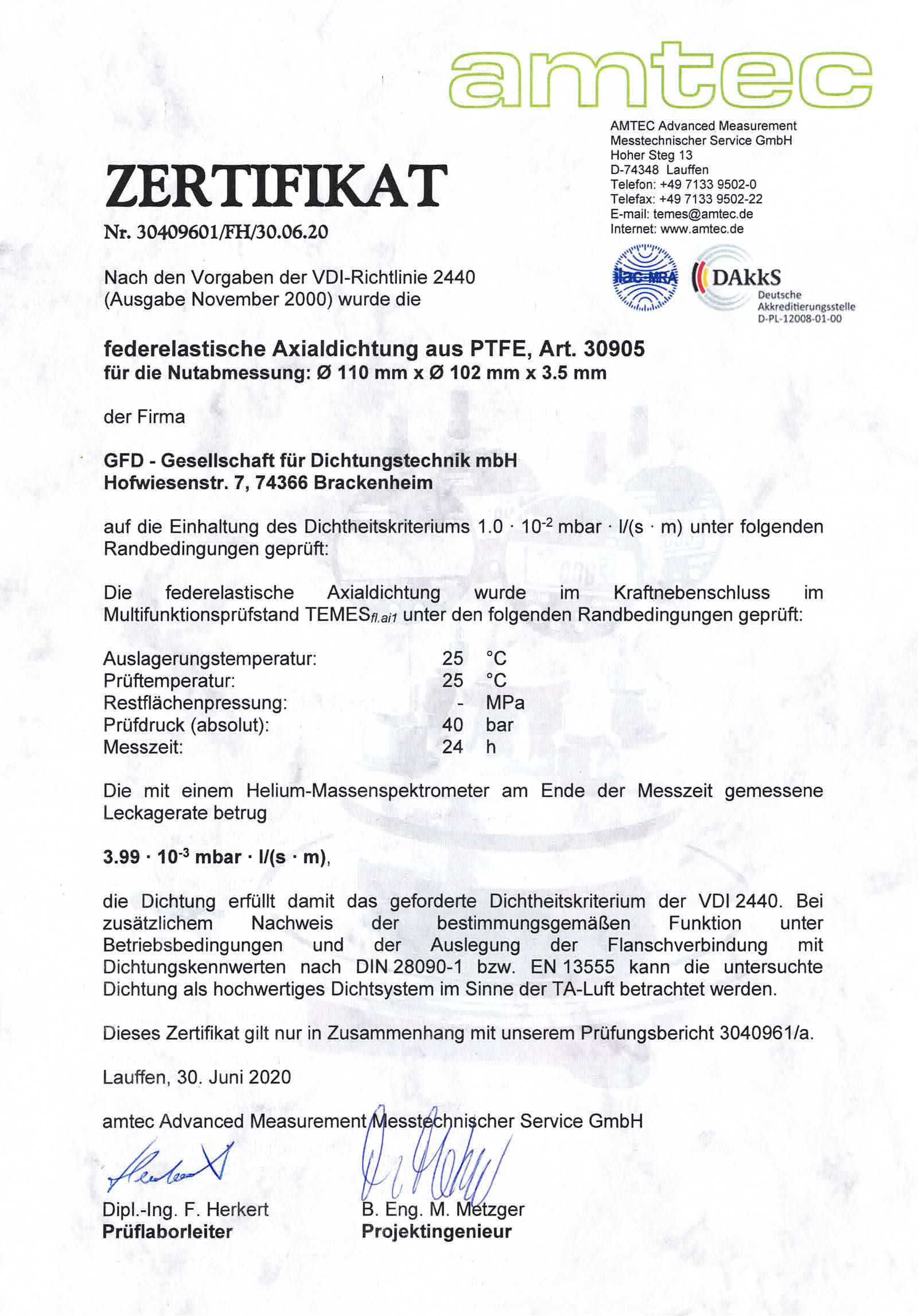

TA-Luft test

According to VDI guideline 2440 (November 2000 edition)

The technical demands on seals are constantly increasing.

More and more often, proof of density according to defined density classes is required.

In order to meet the requirements of the TA-Luft (German Clean Air Act) in particular, we have had GFD spring-energized lip seals tested and certified accordingly.

In cooperation with the company AMTEC Advanced Measurement Messtechnischer Service GmbH a specified leak test was carried out and certified.

The density requirement specified in the guideline VDI 2440 was achieved with the GFD spring-energized axial seal. For detailed technical advice and information on the test report, please contact us.

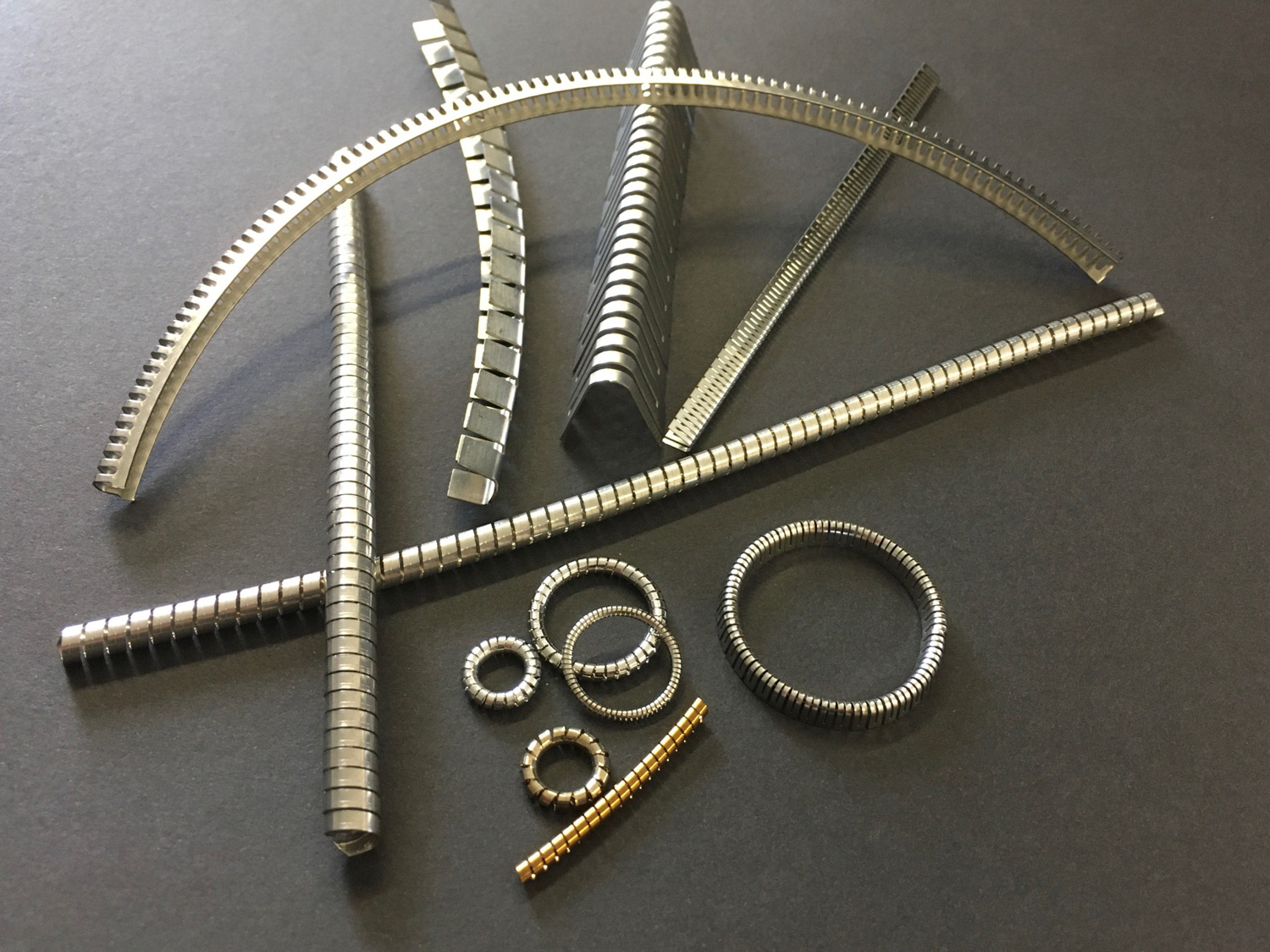

Determination of force characteristics on GFD spring

An important factor in seal design is the spring in the sealing jacket. With its preloading force, this ensures high and lasting elasticity and produces constant and defined sealing loads.

From a sealing technology point of view, it makes sense to adapt the spring force to the application, for example to achieve low leakage through high contact pressure or low friction in dynamic applications.

For special designs or in customer applications, the requirements for the preload forces of the seal can therefore be very individual.

For applications in which, for example, the axial displacement force or torque are the focus of attention, we have a large selection of specially developed springs.

In order to make the appropriate spring selection, the determination of the spring characteristics plays an important role, which can be determined at GFD. For this purpose, suitable in-house testing equipment is available.

Only with the spring characteristic curve it is possible to design the seal in such a way that it works in the optimal operating point and with the desired contact pressure.