MCA (Metal C-Ring for axial pressure application)

Axial pressure application

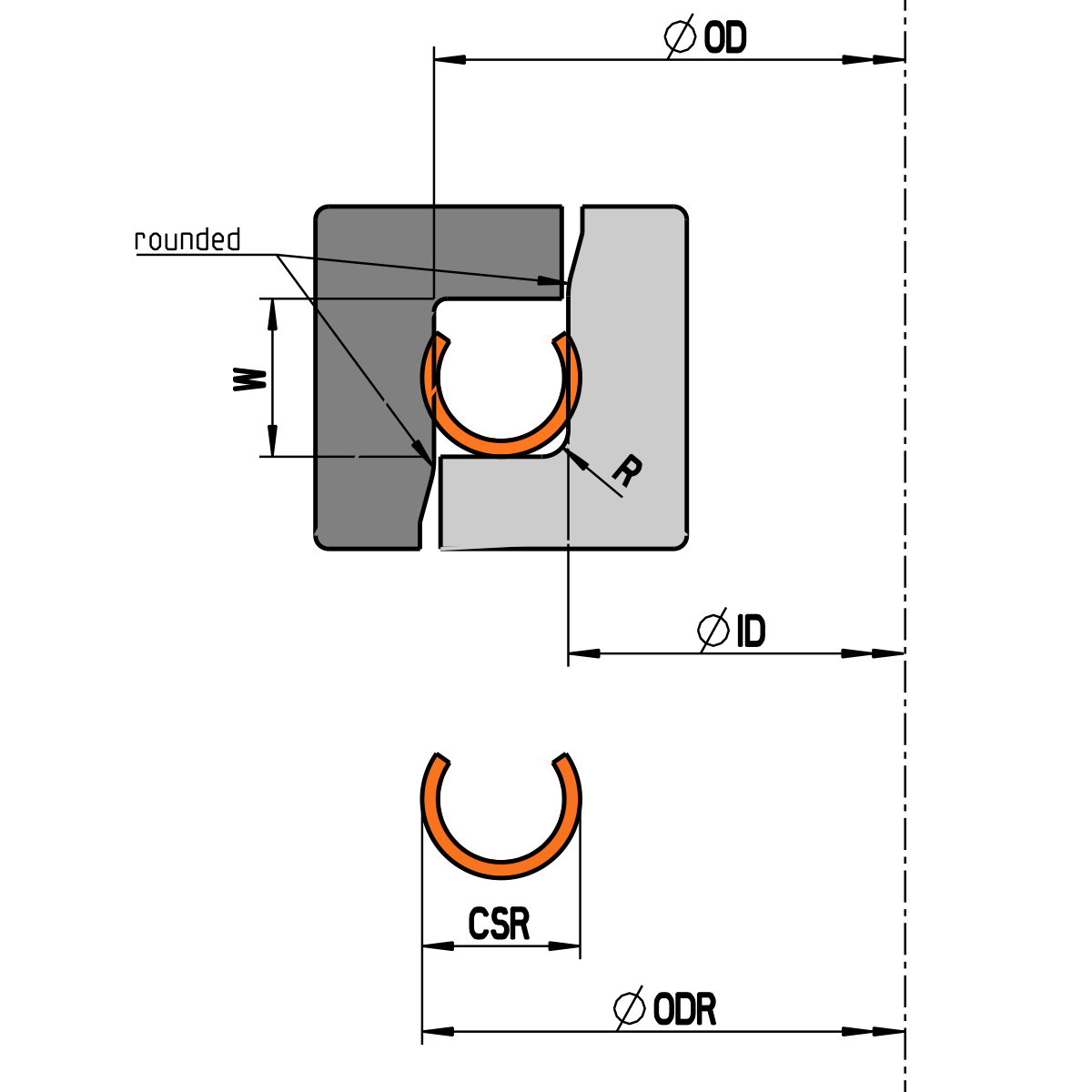

| CSR | Nominal cross-section CSR: Cross-sectional dimension similar to the cord thickness for elastomer O-rings. |

|---|---|

| Code | Performance index: shows the wall thickness of the ring |

| Wt | Wall thickness Wt: Sheet thickness of the ring |

| ODR | Outer diameter of the ring ODR: Diameter range in which the ring can be finished. The outside diameter of the ring is freely selectable in the specified range |

| W | Groove width W min: axial design minimum dimension to ensure pressurization of the ring |

| R | Radius R: Design dimension that improves the support of the ring when pressurized. |

| OD | Outer diameter of the groove OD: corresponding design dimension to the outer diameter of the ring |

| ID | Inner diameter of the groove ID: corresponding design dimension to the outer diameter of the groove |

The following ordering example describes a metal C-Ring for axial pressure application Typ MCA in

7

Material Inconel 718

3,18

Cross section 3,18 mm

w

with wall thickness 0,38 mm

0175,30

Ring outer diameter ODR 175,30 incl. coating

(suitable for groove outer diameter OD 175,00mm x groove inner diameter ID 168,95mm)

(suitable for groove outer diameter OD 175,00mm x groove inner diameter ID 168,95mm)

1

work hardened

S

Silver coating

M

0.03 - 0.05 mm thick

MCA

-

7

-

3,18

w

-

0175,30

-

1

S

M

| Metall-Ring MCA | Installation space | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nominal cross-section |

Performance index |

Wall thickness | Outer diameter ring |

Outer diameter groove | Inner diameter groove | Groove width | Radius | |||

| Range | Tolerance | Range | Tolerance | |||||||

| CSR mm |

Code | Wt mm |

Ø ODR mm |

Ø OD mm von |

Ø OD mm bis |

Tol. OD mm |

Ø ID mm von |

Tol. ID mm |

W min. mm |

R max. mm |

| 1,57 | w | 0,15 | OD + 0,08 | 12,00 | 37,99 | +0,03 | OD - 3,12 | -0,03 | 1,50 | 0,25 |

| 1,57 | w | 0,15 | OD + 0,10 | 38,00 | 45,00 | +0,03 | OD - 3,07 | -0,03 | 1,50 | 0,25 |

| 2,39 | w | 0,25 | OD + 0,08 | 30,00 | 37,99 | +0,03 | OD - 4,70 | -0,03 | 2,20 | 0,25 |

| 2,39 | w | 0,25 | OD + 0,10 | 38,00 | 85,00 | +0,03 | OD - 4,65 | -0,03 | 2,20 | 0,25 |

| 3,18 | w | 0,38 | OD + 0,10 | 50,00 | 84,99 | +0,03 | OD - 6,25 | -0,03 | 2,80 | 0,35 |

| 3,18 | w | 0,38 | OD + 0,15 | 85,00 | 149,99 | +0,05 | OD - 6,15 | -0,05 | 2,80 | 0,35 |

| 3,18 | w | 0,38 | OD + 0,20 | 150,00 | 200,00 | +0,05 | OD - 6,05 | -0,05 | 2,80 | 0,35 |

| 3,96 | w | 0,38 | OD + 0,15 | 85,00 | 149,99 | +0,05 | OD - 7,72 | -0,05 | 3,50 | 0,5 |

| 3,96 | w | 0,38 | OD + 0,20 | 150,00 | 250,00 | +0,05 | OD - 7,62 | -0,05 | 3,50 | 0,5 |

| 4,78 | w | 0,51 | OD + 0,15 | 100,00 | 149,99 | +0,05 | OD - 9,32 | -0,05 | 4,20 | 0,5 |

| 4,78 | w | 0,51 | OD + 0,20 | 150,00 | 300,00 | +0,05 | OD - 9,22 | -0,05 | 4,20 | 0,5 |

| 6,35 | w | 0,64 | OD + 0,20 | 150,00 | 300,00 | +0,05 | OD - 12,4 | -0,05 | 5,50 | 0,75 |

Ring material

| Ring material | Code | Material no. |

|---|---|---|

| SS304 | 1 | 1.4306 |

| Inconel X-750 | 5 | 2.4669 |

| Inconel 718 | 7 | 2.4668 |

Other materials on request.

Heat treatment

| Heat treatment | Code | Description |

|---|---|---|

| HT 1 | 1 | work hardened |

| HT 2 | 2 | age hardened |

| HT 3 | 3 | Solution annealing + precipitation hardened SC |

| HT 4 | 4 | Solution annealing + precipitation hardened Std |

| HT 5 | 5 | Heat treatment NACE MR 0175 |

Other treatments on request.

Coating

| Coating | Code | max. temperature |

|---|---|---|

| Tin | Z | 200°C |

| PTFE | P | 290°C |

| Silver | S | 430°C (650°C*) |

| Copper | C | 930°C |

| Gold | G | 930°C |

| Nickel | N | 1200°C |

| without | O | – |

* Only valid for non-oxidizing media.

Other materials on request.

Coating thickness

| Coating thickness Pt | Code |

|---|---|

| 0,01 - 0,03 mm | L |

| 0,03 - 0,05 mm | M |

| 0,05 - 0,07 mm | H |

Other coating thicknesses on request.