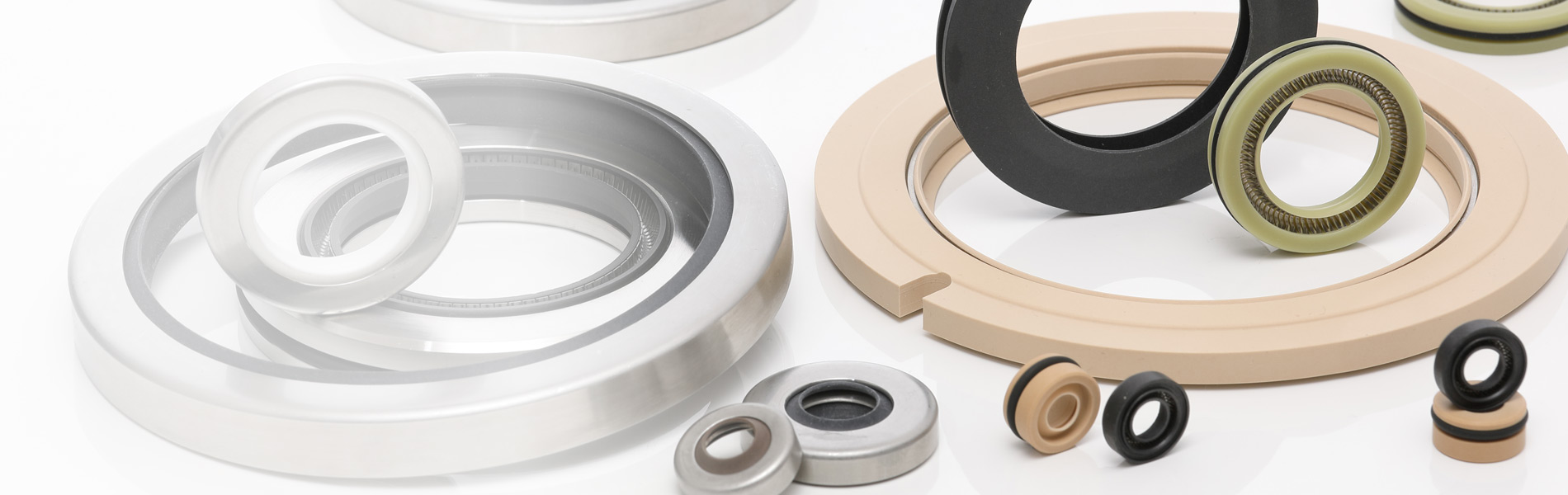

Shaft seals with PTFE sealing lip

Shaft seals with PTFE sealing lip have been specially developed for use in difficult and extreme conditions. They are used when shaft seals with classic elastomer lips reach their performance limits.

Due to the almost universal chemical resistance of PTFE compounds, seals with PTFE sealing lip are particularly suitable for use with chemical, aggressive and corrosive media, pharmaceutical products, various coolants, synthetic oils, heat transfer oils, water and steam.

Thanks to the outstanding properties of PTFE materials and the optimized lip designs, shaft seals with PTFE sealing lip have the following advantages:

- Applicable in a wide temperature range from -70°C to +260°C

- Lowest friction and power consumption due to favorable sliding properties

- Almost universal chemical resistance

- Can be used for dry running and lack of lubrication

- No stick-slip effect, thus low breakaway torque even after longer interruptions

- High circumferential speeds, up to 30 m/s possible

- Pressure load up to 10bar possible

- Use in the food and pharmaceutical industry

General technical information, applications and industries

Shaft seals with PTFE sealing lip

The sealing quality and service life of a shaft seal depend to a large extent on the surface condition of the countersealing surface. The countersealing surfaces must not show any scratches or dents. The same applies to the shaft areas over which the seal is drawn until it is positioned. The areas to be sealed must be free of dust. The shaft may be greased for assembly if the application permits. The grease must be free of solids, e.g. MoS2 or ZnS, and have the appropriate temperature resistance (incl. the resulting frictional heat).

Note:

The operating parameters such as pressure, temperature and speed influence each other. A simultaneous occurrence of the maximum parameters mentioned is therefore not permissible. Please contact our engineering department in such cases.

Typical applications / industries

They can be found for example in:

- Compressors

- Shaft and pump sealings

- Mixers

- Agitators

- Gearboxes

- Centrifuges

- Machine tools or in blowers

The shaft

Shaft seals with PTFE sealing lip ideally run on hard mating surfaces to prevent run-in marks in the shaft. An ideal mating surface is for example the hard chrome-plated running surface. To generate a better match between sealing and mating surfaces, we recommend subjecting these surfaces to a short running-in process.

Our recommendations for the design of the running surface:

Shaft tolerance: h11

Hardness: ideally at least 60 HRC

Surface finish: Ra 0.2 - 0.4

Twist-free groove ground

Lead-in chamfers at shaft end

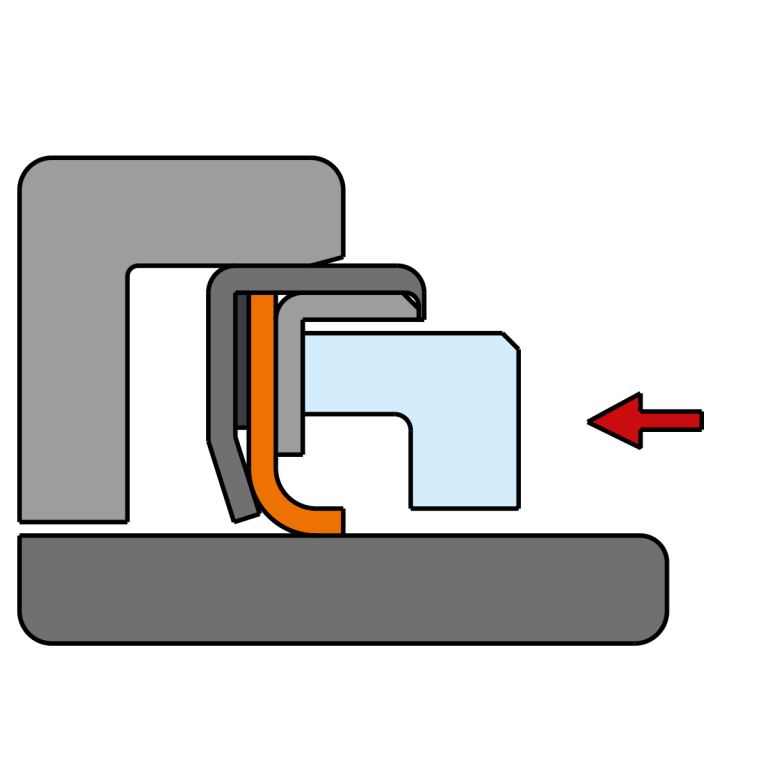

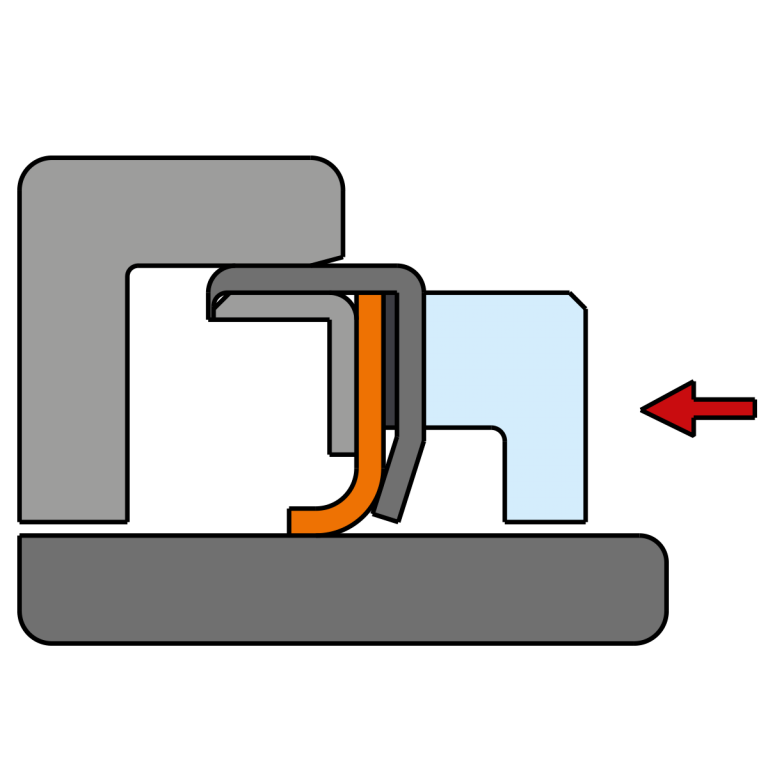

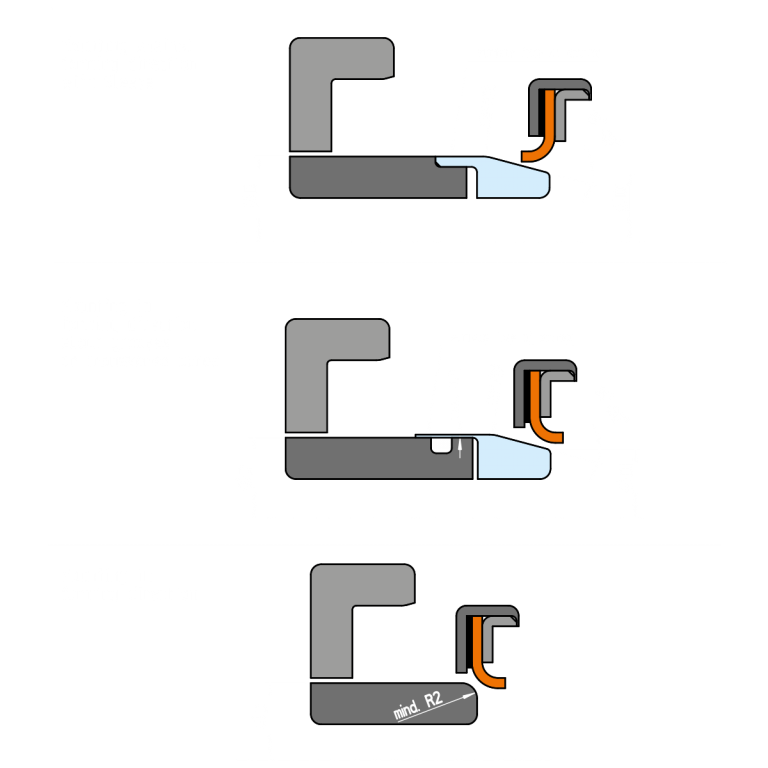

Shaft sealing rings must be fitted extremely gently to avoid damage to the sealing lips.

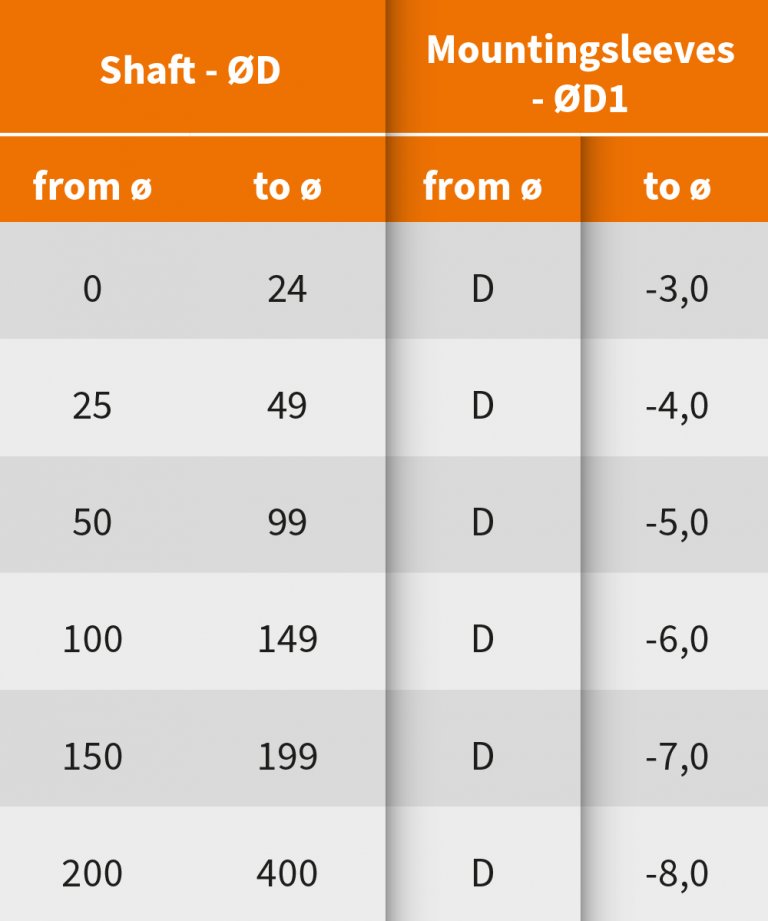

We recommend using press-fit rings for assembly. We are also happy to offer the matching press-fit rings for the shaft seals.

Mounting tools

If shaft seals are mounted against the sealing lip on shafts without sufficient lead-in chamfer, or if they have to be pushed over grooves or transverse bores, we recommend using suitable mounting tools.

These tools must not have any sharp edges or transitions. They must have the same surface quality as the recommended mating surface.

We are also pleased to offer the appropriate mounting tools for the shaft seals.

Eccentricity

To prevent the sealing lip from lifting off the shaft, the shaft runout must be low.

We therefore recommend a concentricity tolerance of maximum 0.05 mm.

Coaxiality

There must be uniform radial contact pressure over the entire circumference of the sealing lip on the shaft to prevent uneven wear.

We recommend a maximum coaxiality of 0.1 mm.

Load

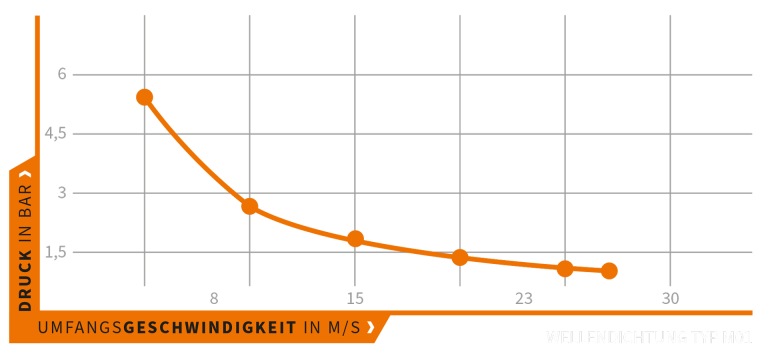

The load on the shaft seal during operation depends mainly on the pressure and the circumferential speed of the shaft. How far the shaft seal is from its load limit, or whether this has been reached or exceeded, can be determined by looking at the pv value. The permissible pv value is shown by the curve in the diagram.

In the case of dry running/lack of lubrication, the value can be greatly reduced.

In this case, please contact our technical department.

Material selection

In addition to the correct choice of design and sealing lip geometry, the correct selection of the lip material is also decisive for the service life. PTFE materials are used as standard and their advantages can cover a wide range of applications.

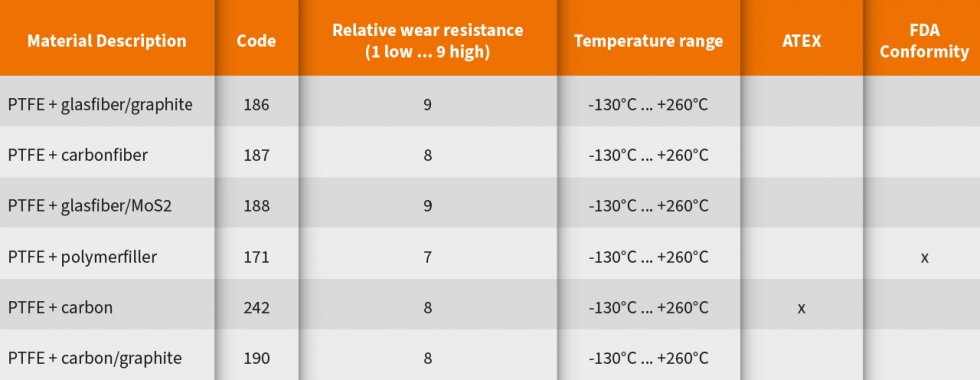

Sealing lip materials

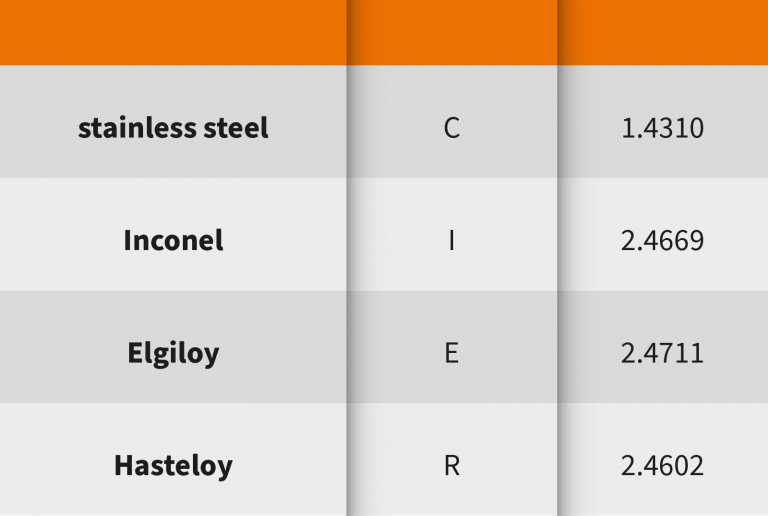

The following PTFE materials are available as standard for shaft seals in stainless steel housings:

Housing material

The housing is made of stainless steel 1.4301 (ss 304). Alternatively it is also possible in 1.4401 (ss 316)

Match code for rotary shaft seals with stainless steel housing

The following information is required for the seal definition of the shaft seal:

Example

RWDR - (type) - (groove dimension) - PTFE material

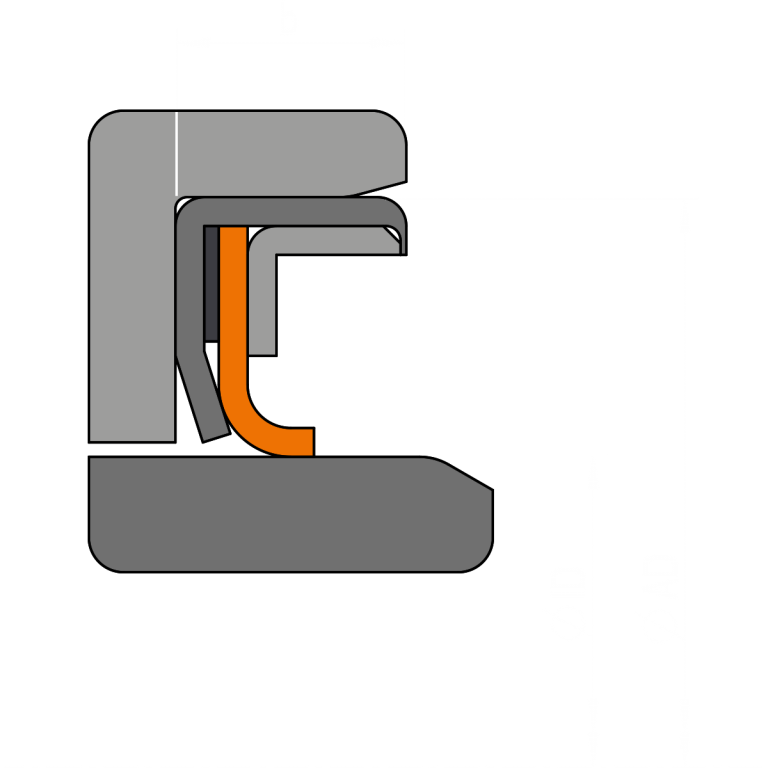

Shaft seal types with stainless steel housing

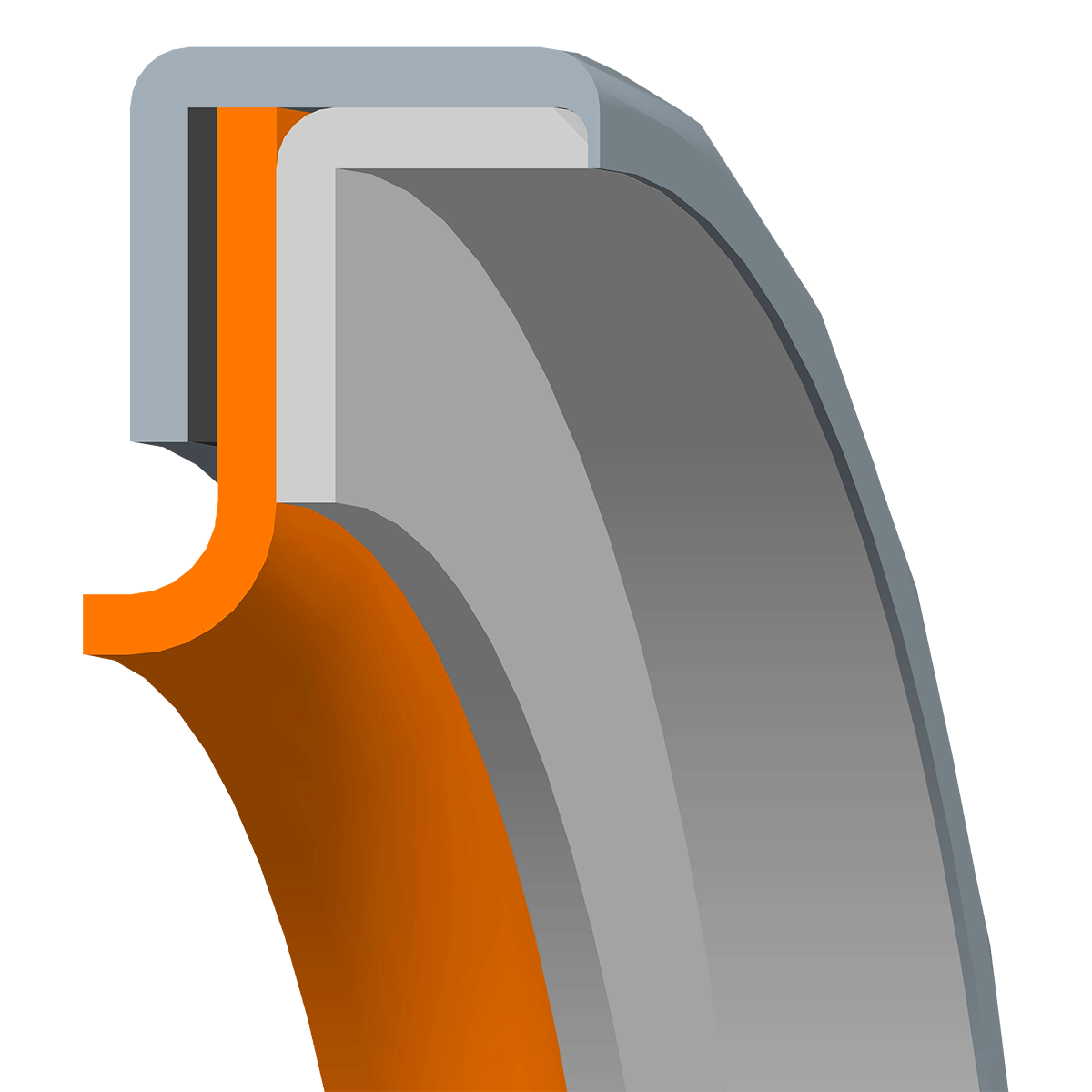

The sealing lips are set in a corrosion-resistant stainless steel housing which is pressed into the location bore. The bore should therefore be made of steel or cast iron. The dimensions of the sealing rings are comparable with shaft seals to DIN 3760 and can therefore be easily replaced.

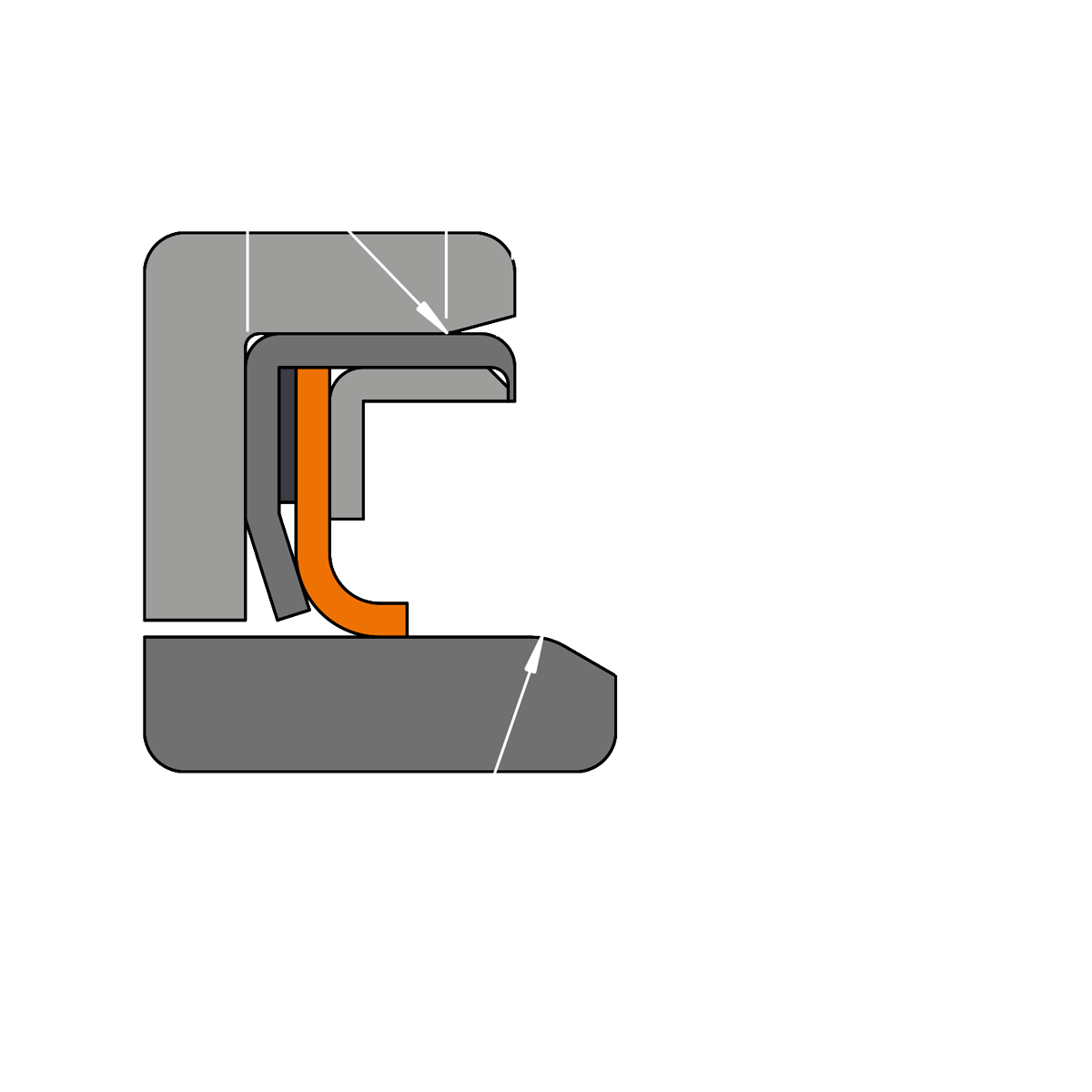

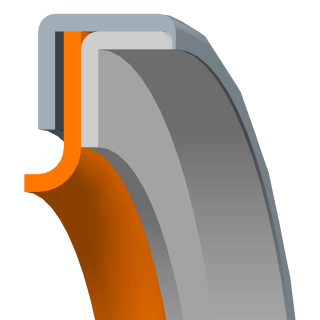

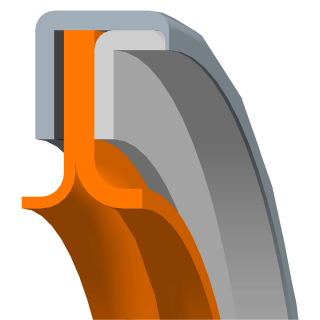

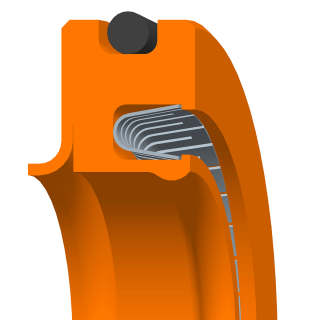

Type M01

Standard seal with supported sealing lip

Application limits:

Temperatures: -40°C - +260°C

Max. Pressure: 10 bar

Max. Peripheral speed: 30 m/s

Example: Compressors, mixers, agitators, gearboxes, vacuum pumps

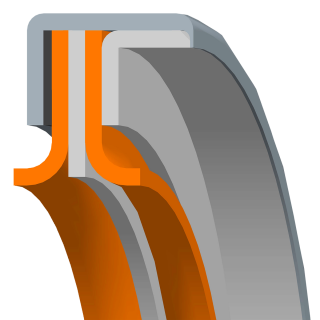

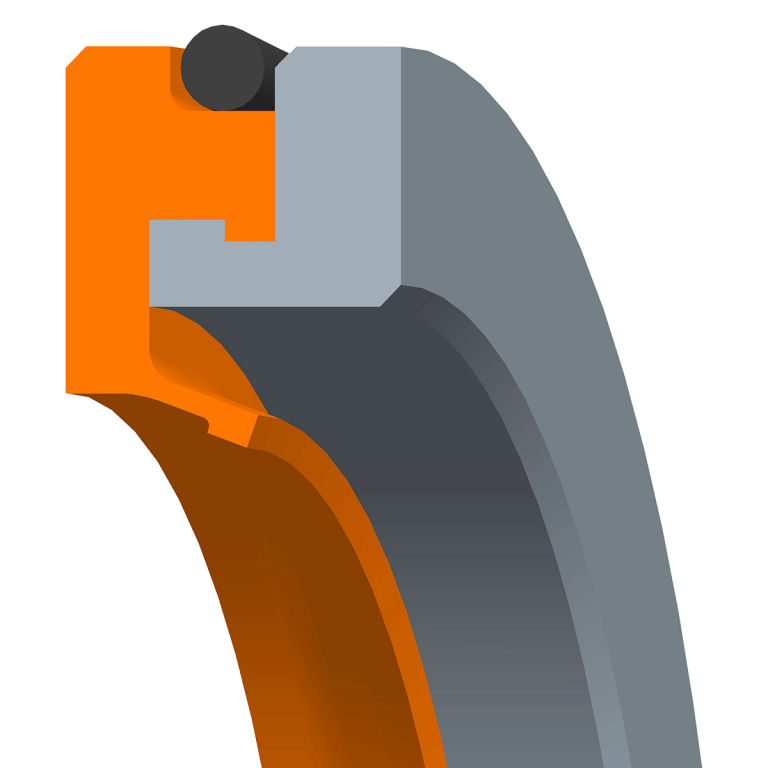

Type M

With straight metal housing.

Example: Compressors, agitators, planetary gearboxes, compressors

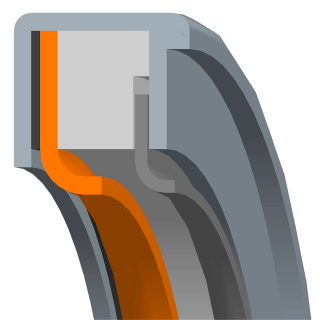

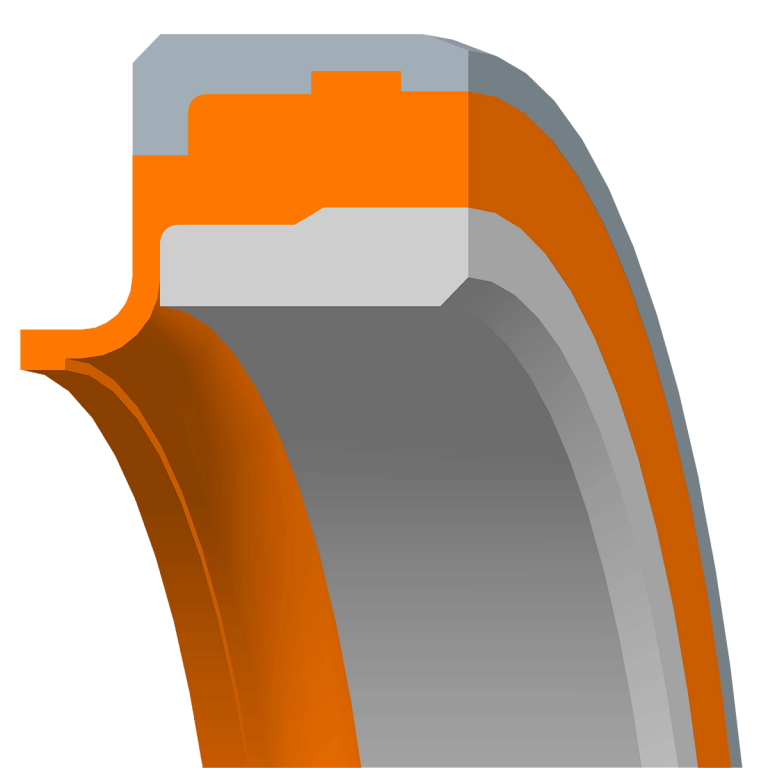

Type M04

With negatively shaped sealing lip. Ideal for applications where no dead spaces are permitted, for example in the food and pharmaceutical industries.

Example: Planetary gearboxes, filter centrifuges, dryers, centrifuges, agitators

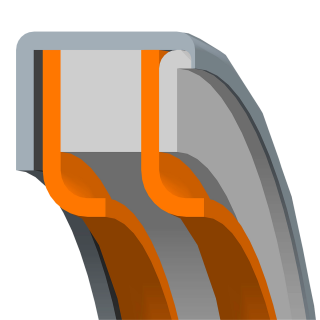

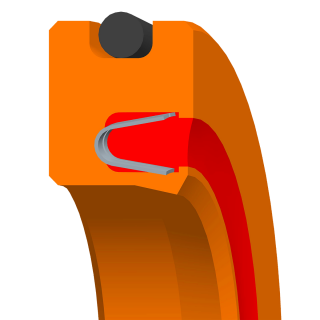

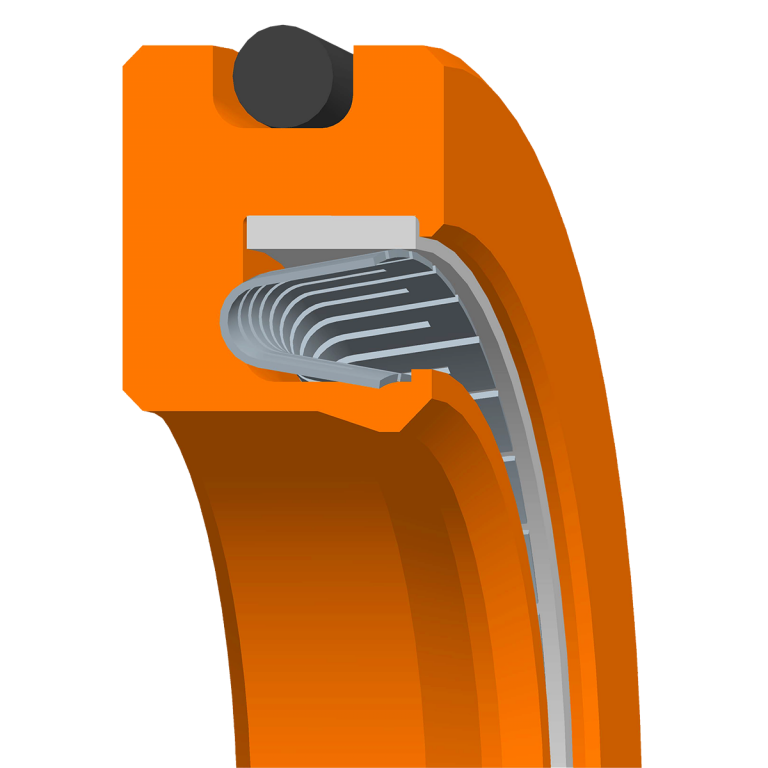

Type MD

For applications where a higher sealing effect is required, such as e.g. gaseous or critical media.

Also offers the possibility to fill the gap with a disposable lubricant.

Example: Vacuum pumps

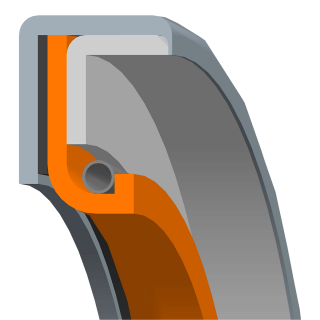

Type MF

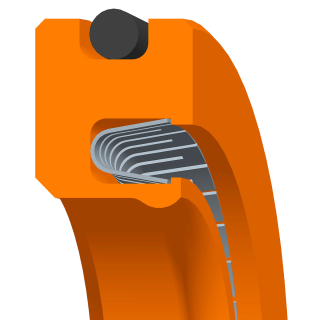

Spring-energized sealing lip for increased tightness requirements to allow better lip tracking at low shaft runout.

The spring increases the standstill tightness in pressureless condition.

Example: Pumps

Type MW

With scraper lip, which prevents abrasive particles from depositing under the sealing lip. Ideal for dusty and dirty environments.

Example: Radial piston pumps, granulating systems, mixers

In addition, we offer further individual solutions to shaft seals with PTFE sealing lip in stainless steel housing in order to be able to offer an even better adaptation to customer-specific applications.

The following is an excerpt from our range of designs:

Note:

All shaft seals can also be manufactured in a low-friction version. Likewise the respective medium lip can be equipped with a return thrust.

However the running direction of the shaft must be known beforehand.

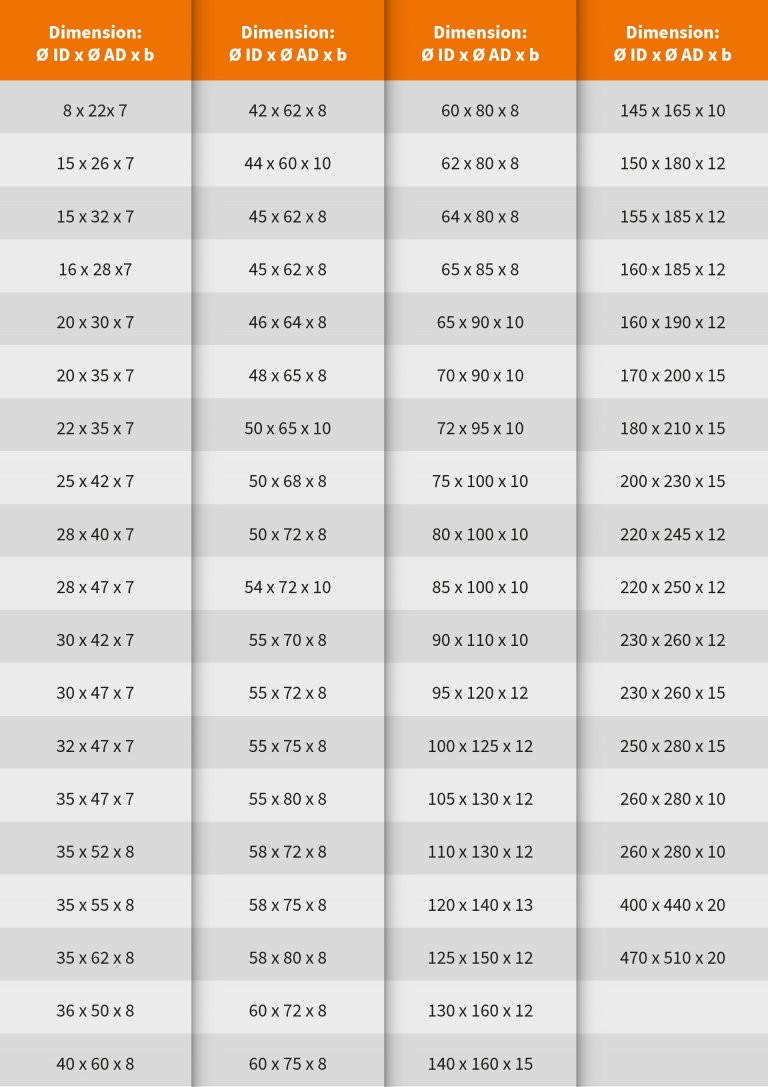

Dimensions list, standard type M01

We stock many common dimensions of the standard type M01. In addition, we manufacture these rings in any intermediate dimensions.

Seals up to shaft diameter Ø 470 mm are possible.

Shaft seals without housing

Shaft seals without housing are individual solutions that do not require a stainless steel housing. This allows a larger diameter range from Ø 1.5 - Ø 3000 mm.

Furthermore, the production of smaller lot sizes is possible and can also be manufactured in many special compounds at short term.

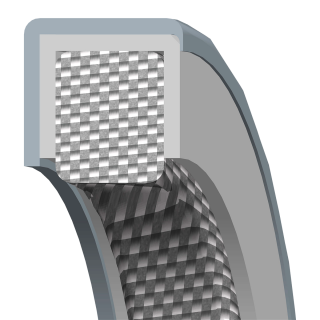

In addition to the classic formed sealing lip, the lip can also be equipped with a spring which, among other things, ensures that the contact pressure of the lip on the shaft remains constant even in the event of temperature fluctuations.

For designs without dead space, the spring space is filled with red silicone (FDA) after spring assembly. Some applications even allow the use of an O-ring as a preload element of the sealing lip and simultaneous dead space solution.

This type of seal without a stainless steel housing is also pressed into a location hole. Unlike the shaft seal with stainless steel housing, however, this does not always have to be made of steel or cast iron. The locating bore can also be made of plastic.

An elastomer O-ring is fitted to the outer diameter of the sealing ring, which provides the static seal between the sealing element and the bore.

We recommend clamping the shaft seals axially to prevent them from rotating.

The areas of application conform to the shaft sealing rings with stainless steel housing.

RWDR oG MD

The double-lipped design offers more safety with more critical media.

Example: Screw conveyors, mixers, agitators

RWDR oG 400

This version has a spring-energized sealing lip.

Example: Drum motor, parts cleaning machines

RWDR oG 4VSSR

The spring space is additionally filled with red silicone. This prevents product from accumulating in the groove or germs from entering the spring spaces.

Example: Mixers, agitators for the food industry

In addition, we offer further individual solutions to shaft seals with PTFE sealing lip without stainless steel housing, in order to be able to offer an even better adaptation to the customer-specific applications.

Excerpt from our range of types: